Atlas customer, Beneq, a leading supplier of production and research equipment for thin film atomic layer deposition and aerosol coatings, as well as the world’s premier manufacturer of thin film electroluminescent (TFEL) displays, has brought many interesting projects to our design tables and manufacturing facility.

Late last year, Beneq brought us a design challenge for a water-cooled aluminum chamber to be used with the TFS 200 ALD, the most flexible platform ever designed for research and development.

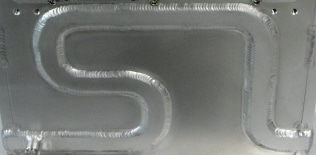

This particular chamber was designed to alternately deposit gas and water vapor with the cooling channels welded to the outside of the chamber. The welded channels posed a manufacturing challenge and raised the cost to needlessly. Our Production Manager, Tom Casey, worked to simplify the design and, ultimately, Atlas and Beneq agreed to a revision which allowed Atlas to cut and cap the channels directly into the exterior sides of the chamber.