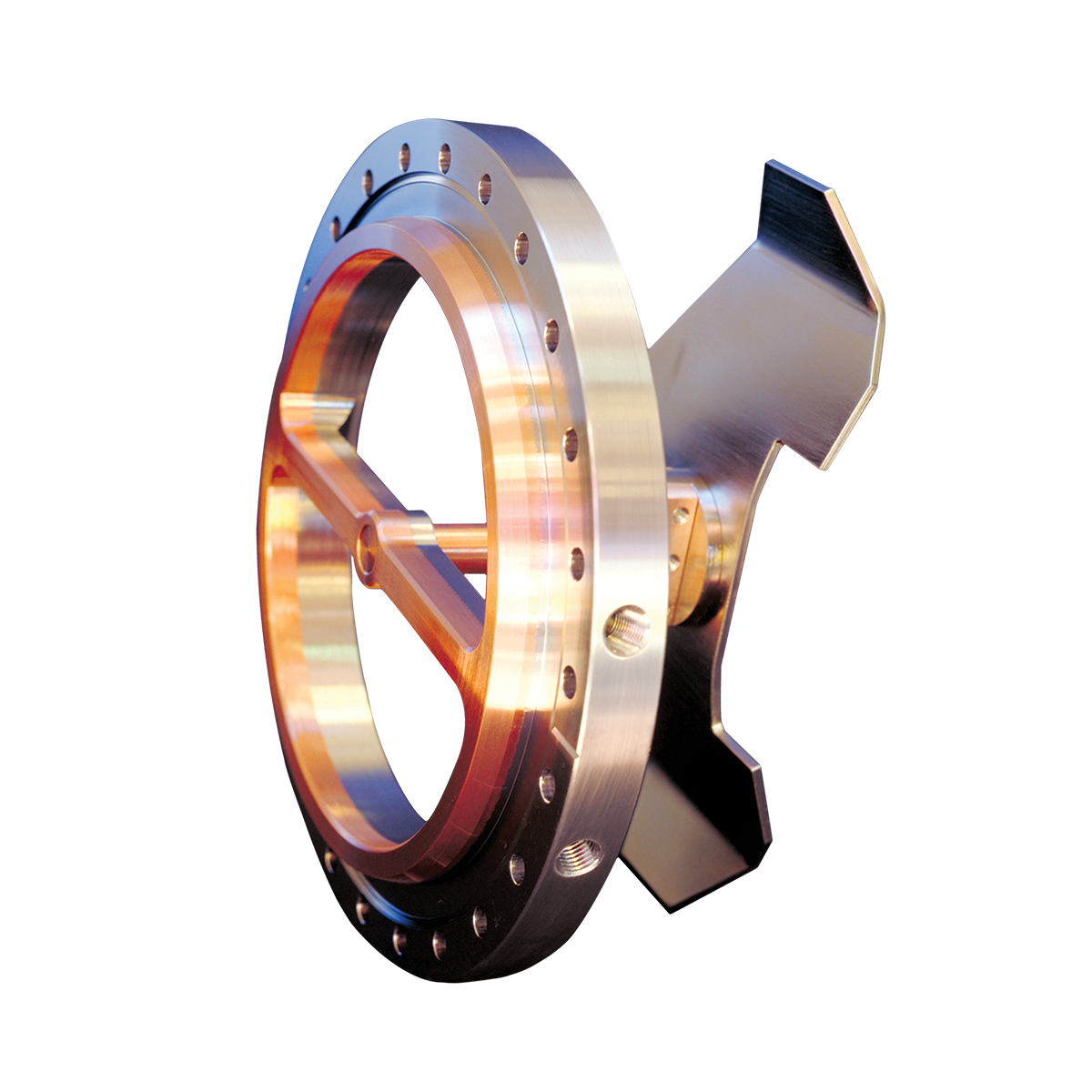

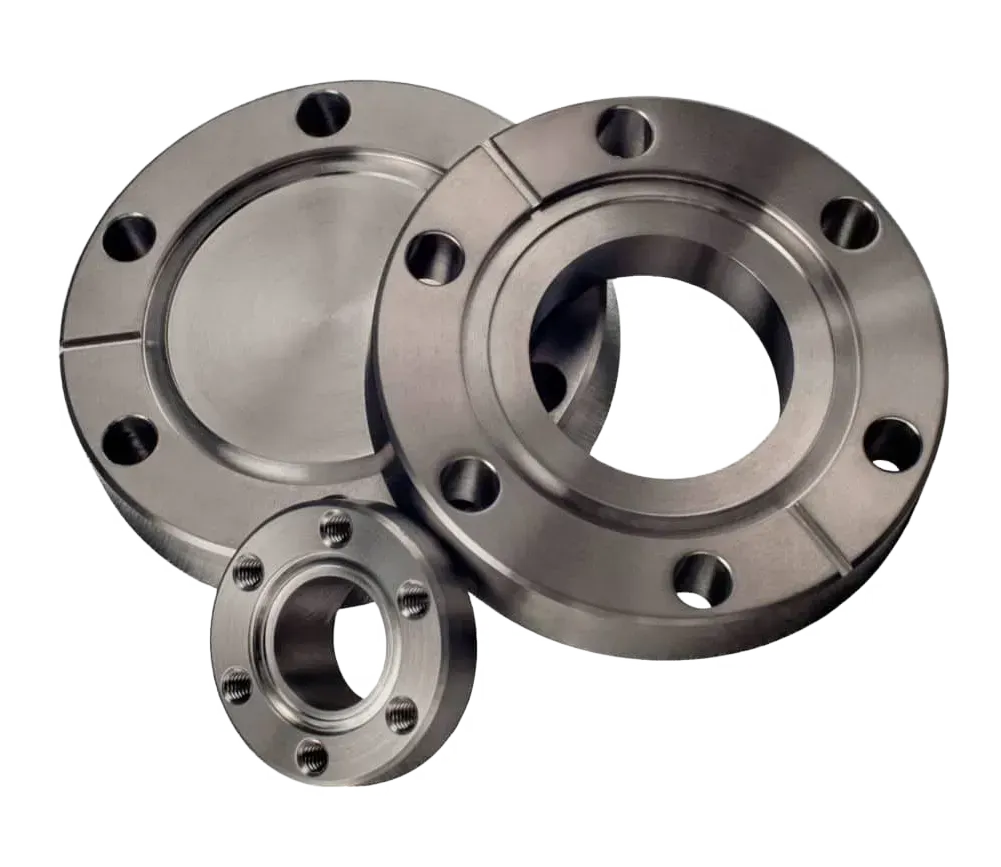

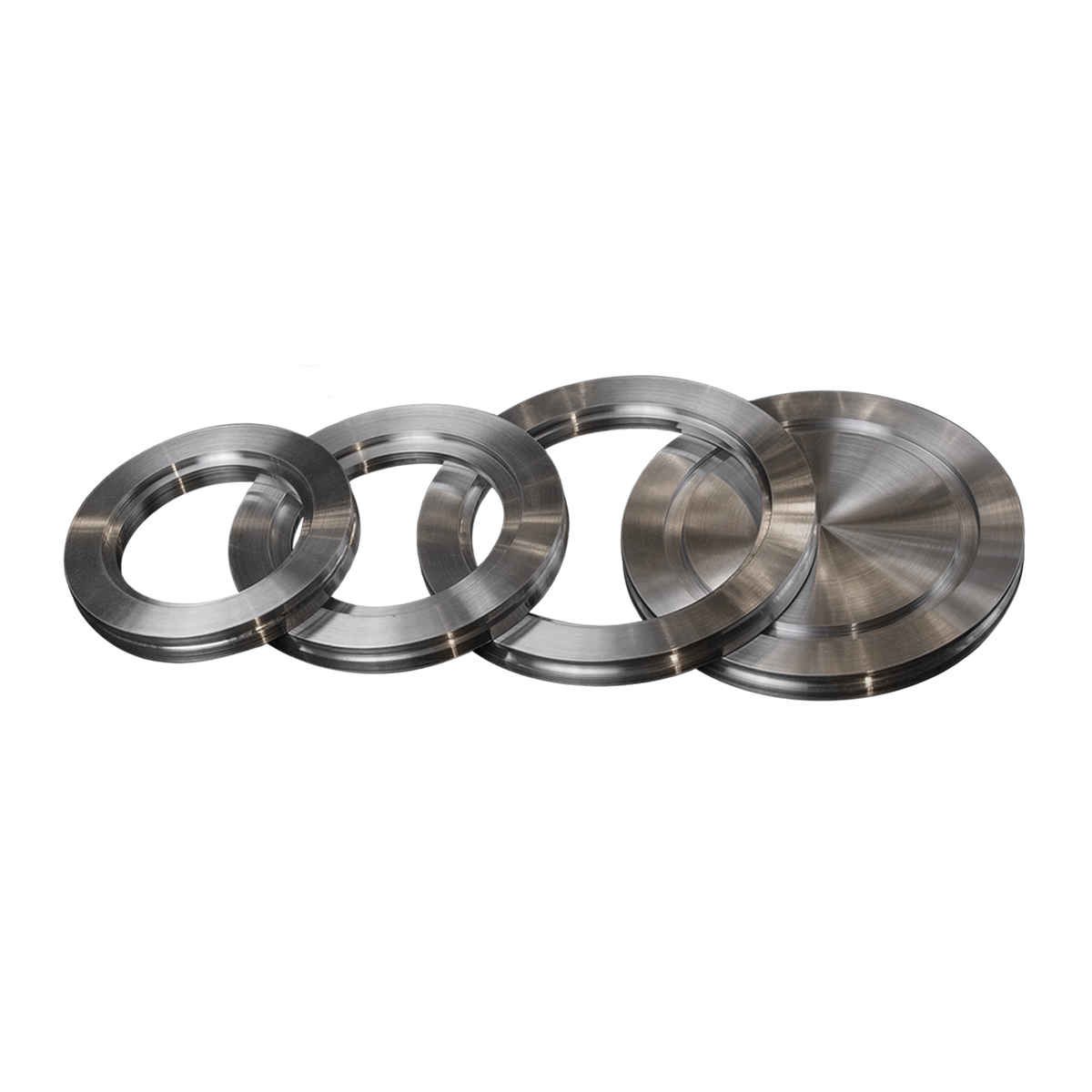

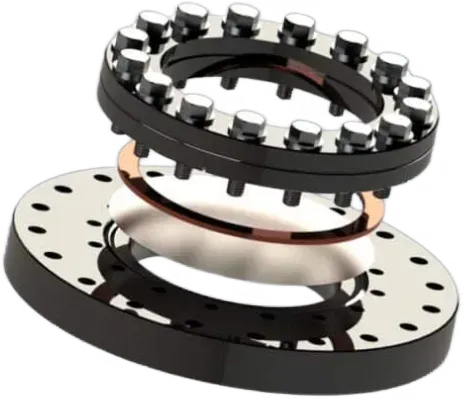

Bimetal components & UHV solutions

HOW CAN WE ASSIST IN YOUR PRODUCT DEVELOPMENT NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a rough sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.