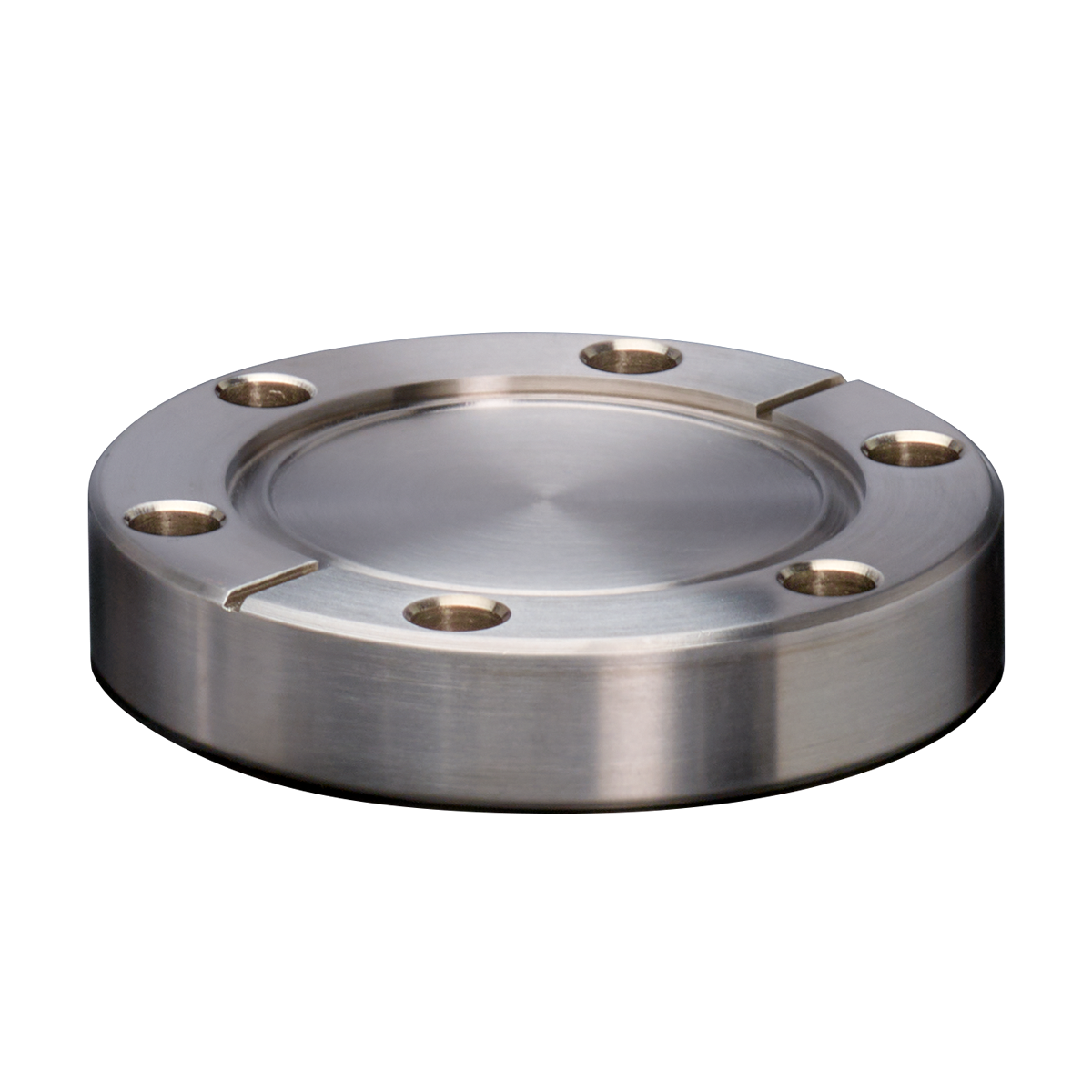

Non-Magnetic UHV & XHV Conflat Titanium Flanges

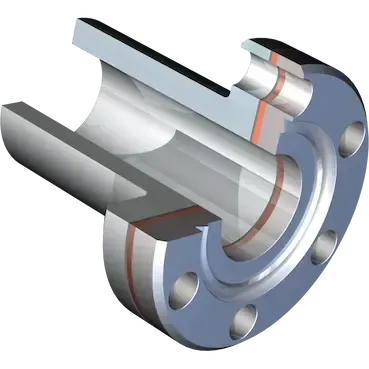

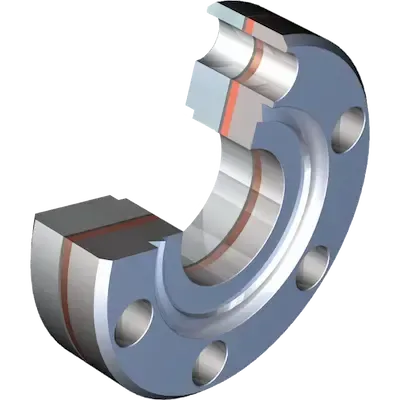

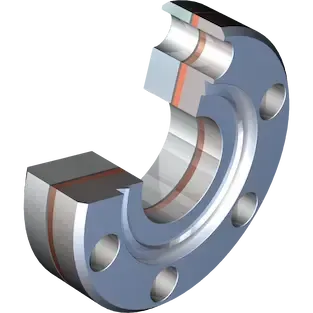

Atlas Titanium ConFlat Flanges feature the reliability of the industry-standard CF knife edge. Weld the titanium flange to a titanium vacuum chamber, and it becomes a completely non-magnetic system. Titanium vacuum chambers with titanium flanges ensure no environmental magnetic interaction and deliver extraordinary vacuum performance.

Applications:

- UHV synchrotron

- Particle physics

- Industrial applications

- XHV quantum physics

- Beam tubes

- Wigglers and undulators

- Free electron lasers (FEL)

- Drift tubes

- Spectrometers

Light/Low Weight Atlas Flanges:

- Ideal for weight sensitive applications such as aerospace or portable systems

- Weight-to-volume ratios are 1/3 that of stainless steel flanges

- Significantly reduces overall weight of vacuum chambers