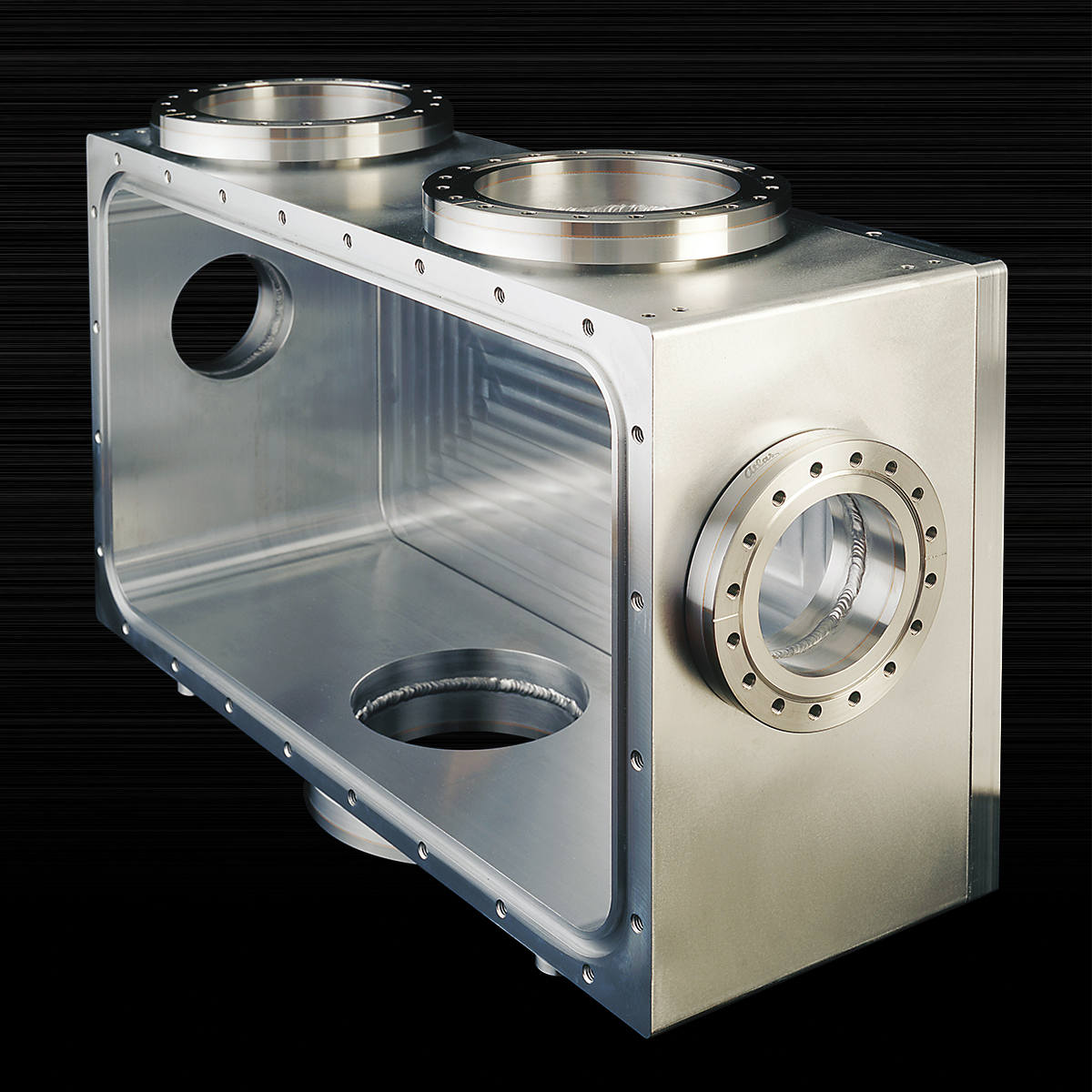

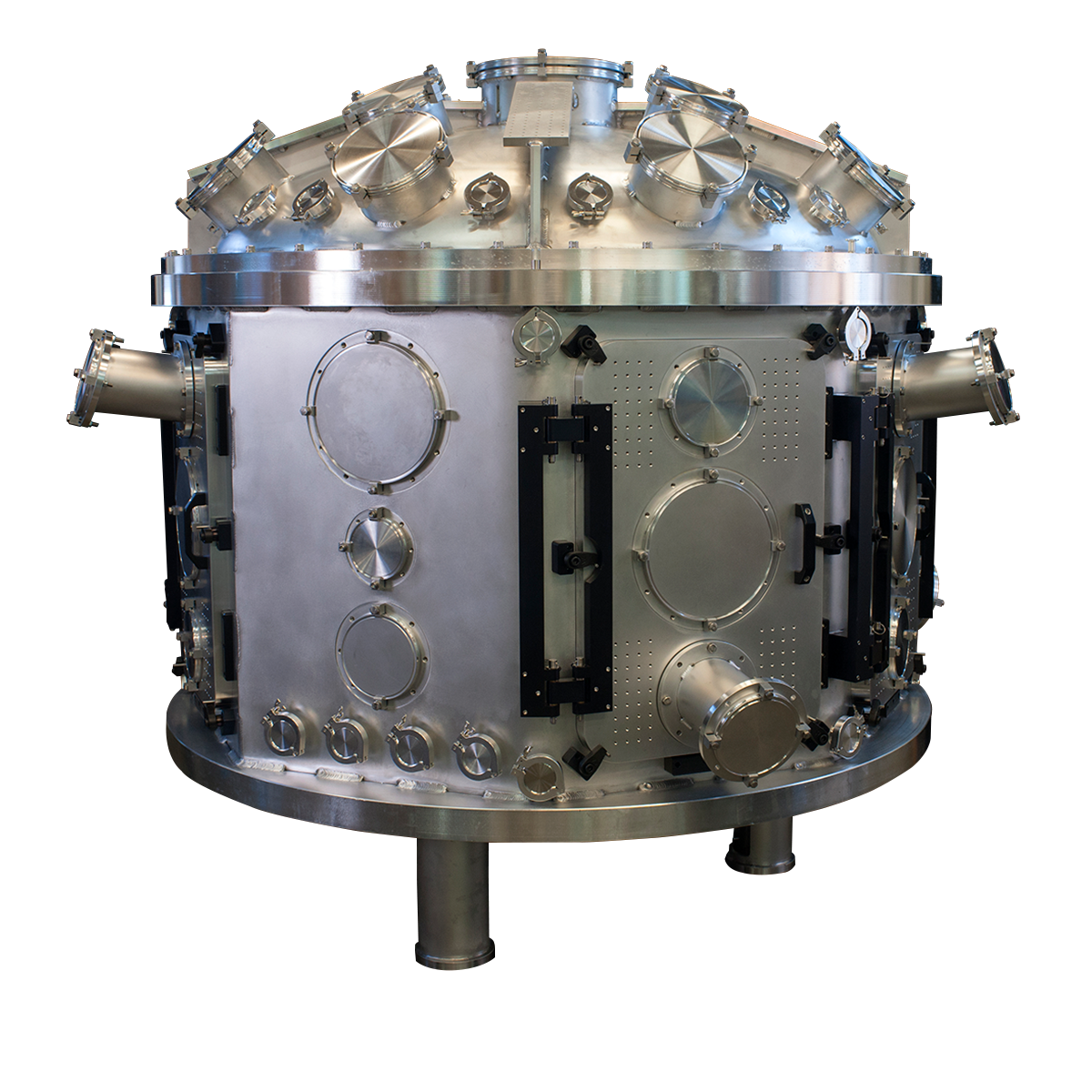

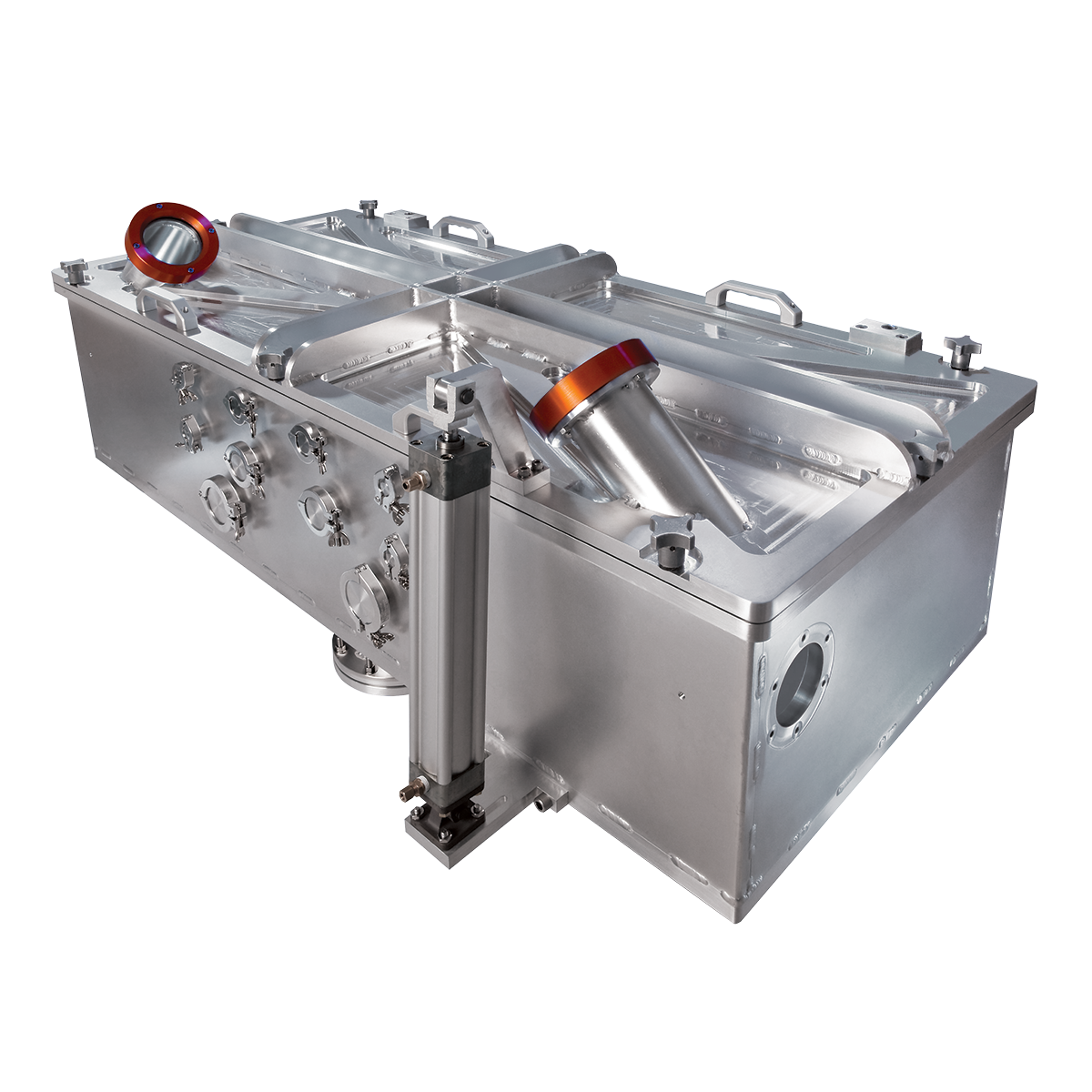

Custom Vacuum Chambers

VACUUM ACCESSORIES

As a part of designing and building your custom vacuum chambers and systems, Atlas offers various additional components:

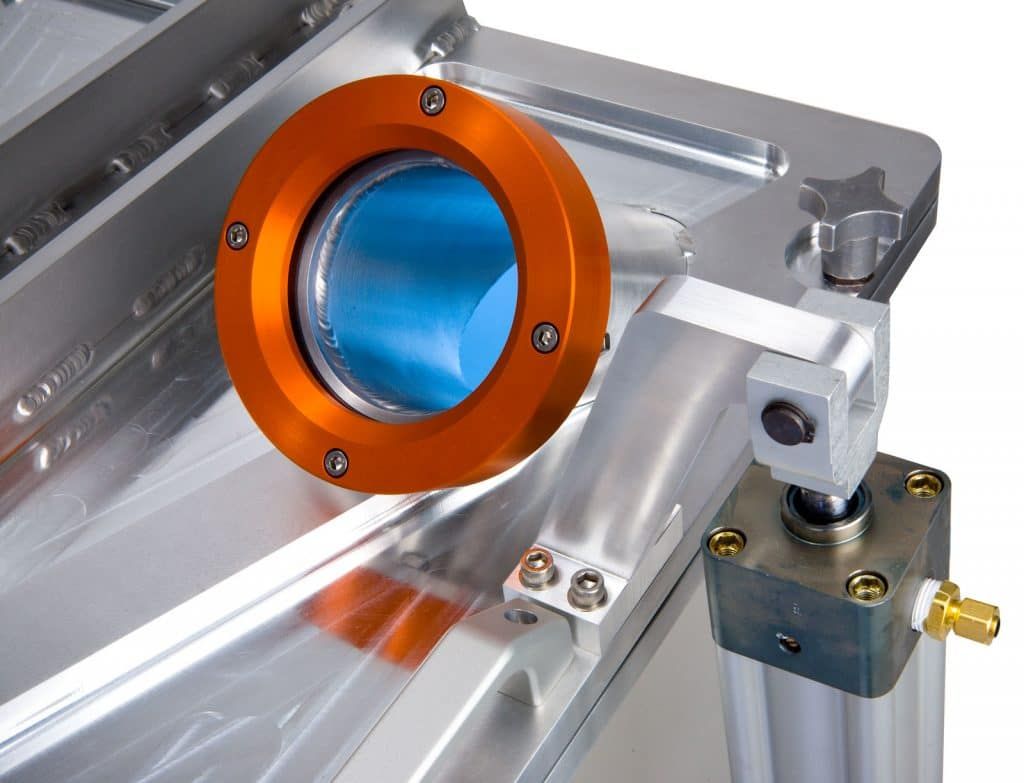

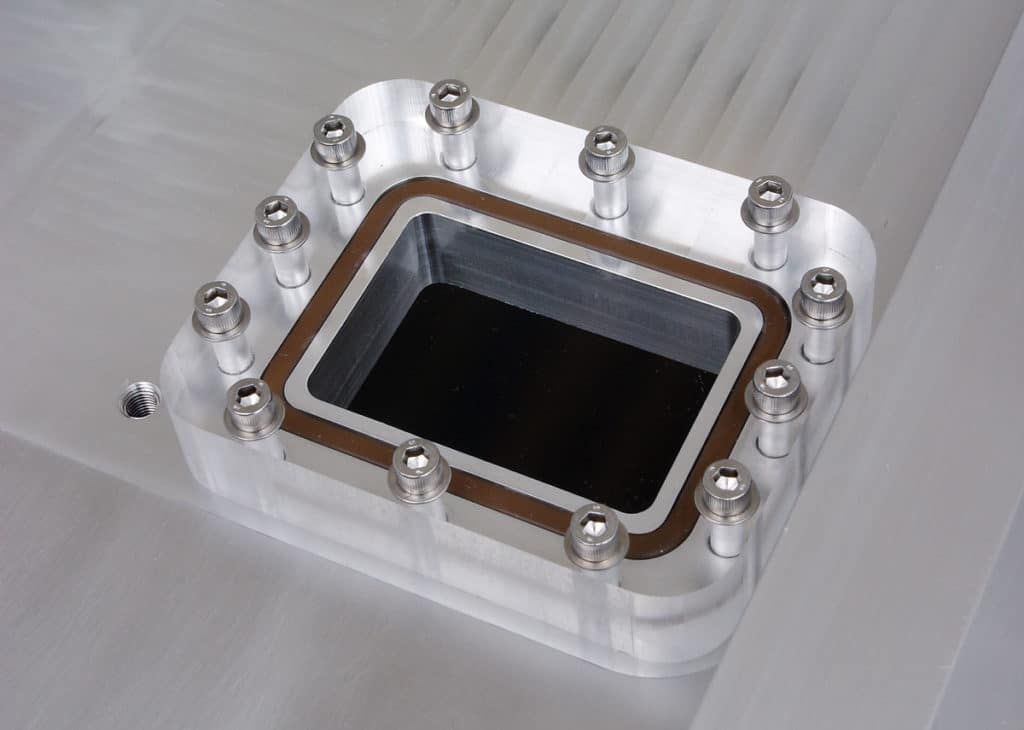

- Atlas Polycarbonate Windows offer cost-effective, customizable acrylic viewports useful for industrial and scientific environments

- Atlas ISO Pyrex Windows with aluminum bezel and centering ring are used for HV chamber viewports and are available with ISO claw-clamp fasteners, and nut and bolt fasteners.

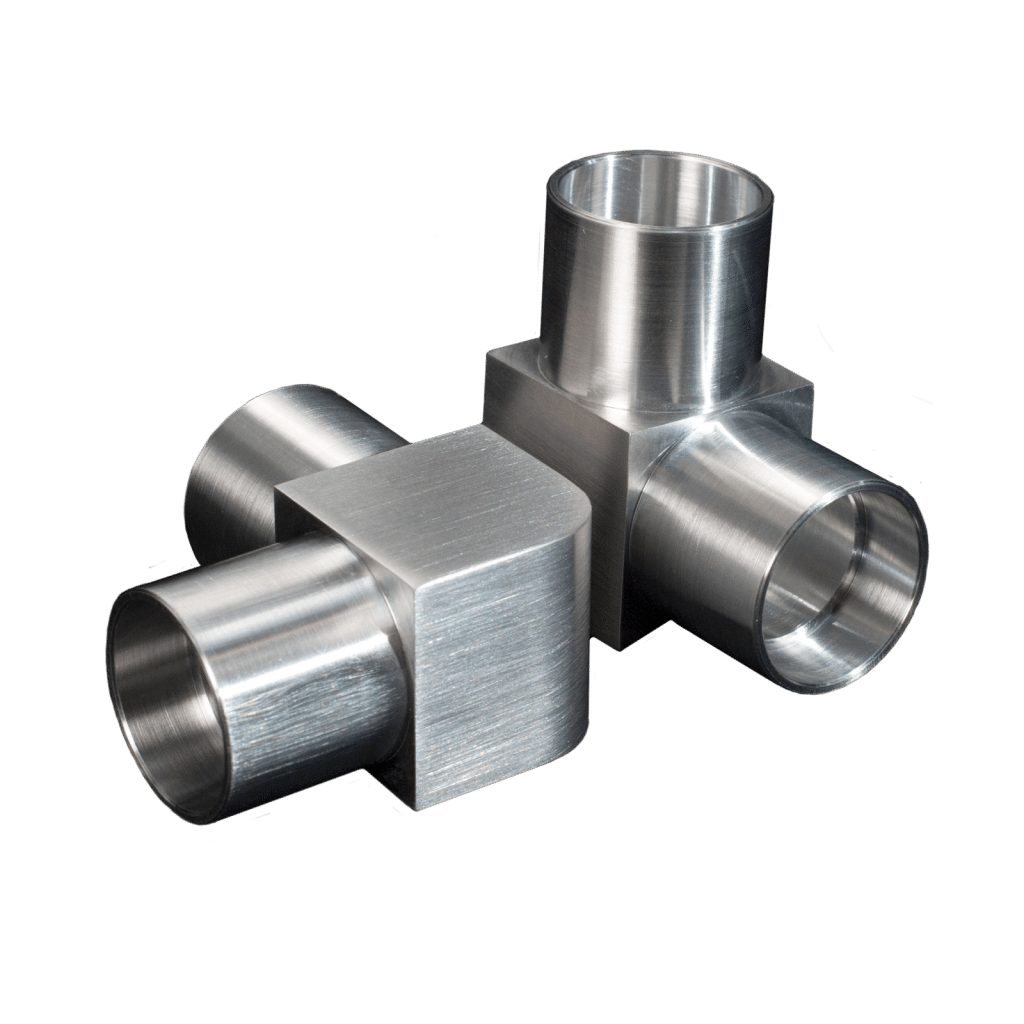

- Nipples and half-nipples as well as elbows, tees, and crosses are also available as part of your chamber or system.

All components are precision manufactured and rigorously tested to UHV standards as a part of your order.

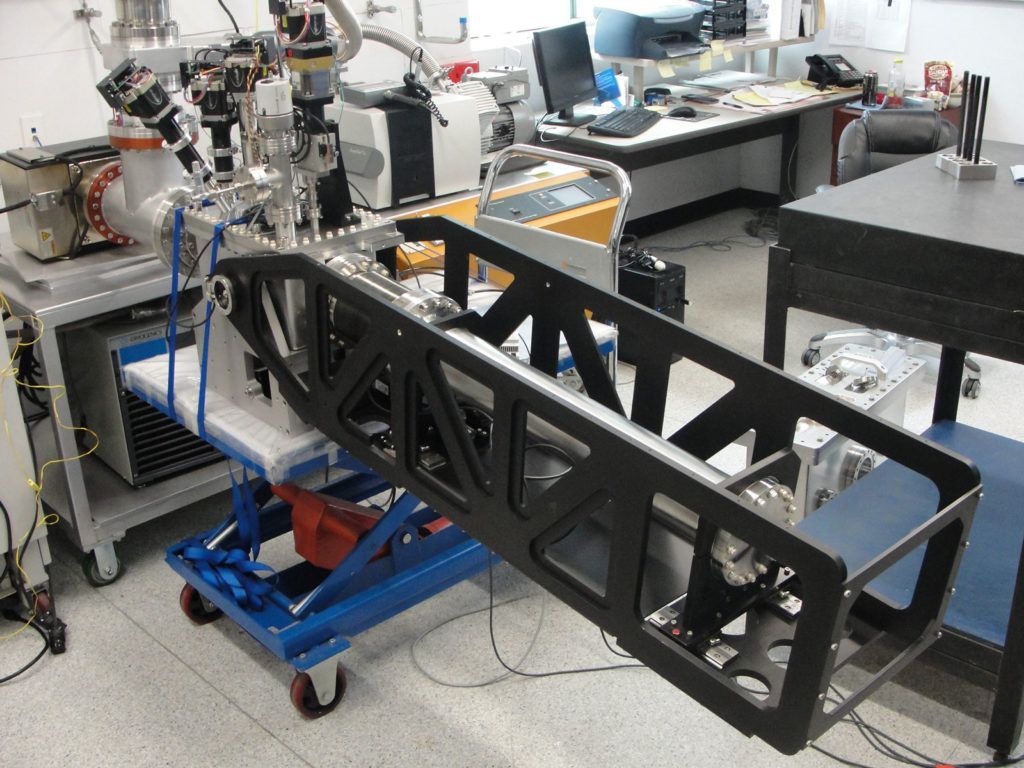

Vacuum Systems

Integrating and optimizing a vacuum system can be daunting. Every element of your system has subtle factors that affect performance. Many low-cost, easy-to-implement optimizations can have a big impact on performance, such as shorter fore-line lengths and avoiding unnecessary obstructions in pump lines.

We find that customers often revert to costly pump systems to improve pump-down times or to gain higher vacuum when the performance can be improved much less expensively with better design, valve, or material choices.

Atlas has considerable experience integrating vacuum systems. We are happy to help you integrate yours in our comprehensive vacuum testing laboratory.

Contact an Atlas salesperson today to learn how we can help you with your vacuum system needs.

Vacuum Design & Engineering

The design of your vacuum system will have a huge impact on its performance. A good design will get you the performance you require (base pressure, pump-down speed, etc.) without excessive pumping costs.

For UHV and XHV, poor vacuum design can make it impossible to reach base pressure goals no matter the pumping method. We’ve seen many instances where people add bigger pumps to their vacuum systems in an attempt to reach a desired base pressure. However, this energy-intensive approach ends up being significantly more expensive when a better design can achieve the same goal.

Our extensive experience with vacuum systems and a range of materials allows us to reach your design pressure goals more efficiently. Many of the chambers and products we produce have been redesigned or modified by Atlas to enhance manufacturability or improve vacuum performance.

Contact an Atlas salesperson today to learn how we can help you with your vacuum system needs.

HOW CAN WE help with your next vacuum project?

We build custom HV, UHV, and XHV vacuum chambers for customers worldwide. From UHV suitcases to atmospheric test chambers to quantum computing enclosures, we've done it all. Let us know how we can help you.