Blog

Written by: Richard Bothell and Justin Bothell, Atlas Technologies; Glen Tisdale, Judith Offerle, UHV Aluminum Company Achieving sub-micron feature sizes on a production basis requires an understanding of the complete processing environment including the vacuum reactor itself. Molecular level chemical contamination demands that all processes factor in the vacuum environment. The vacuum system base pressures are a critical parameter in determining the environmental contribution to wafer contamination. Actual processing levels may be decades above the base pressure, but the base pressure establishes the environmental noise of the system.

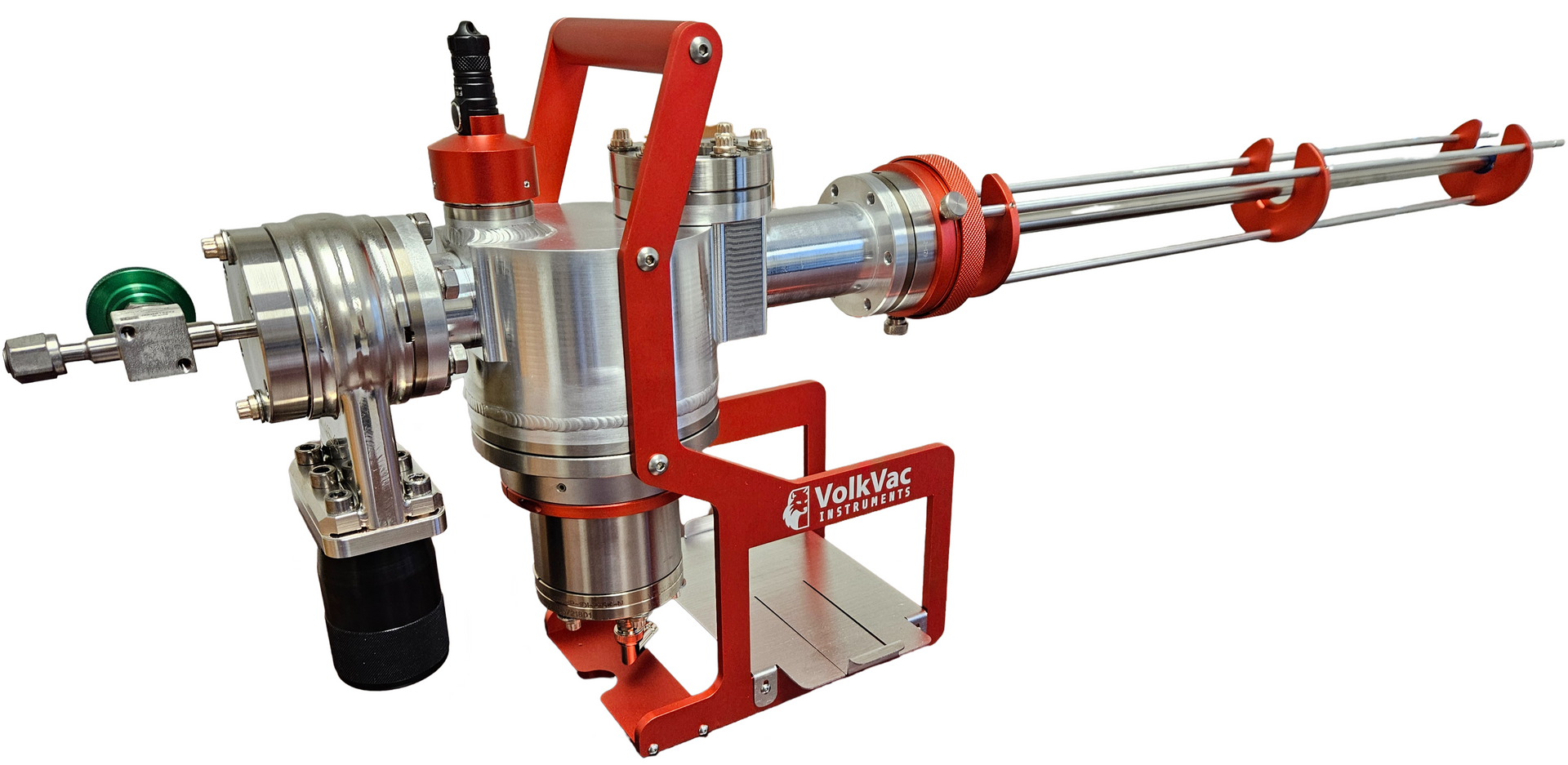

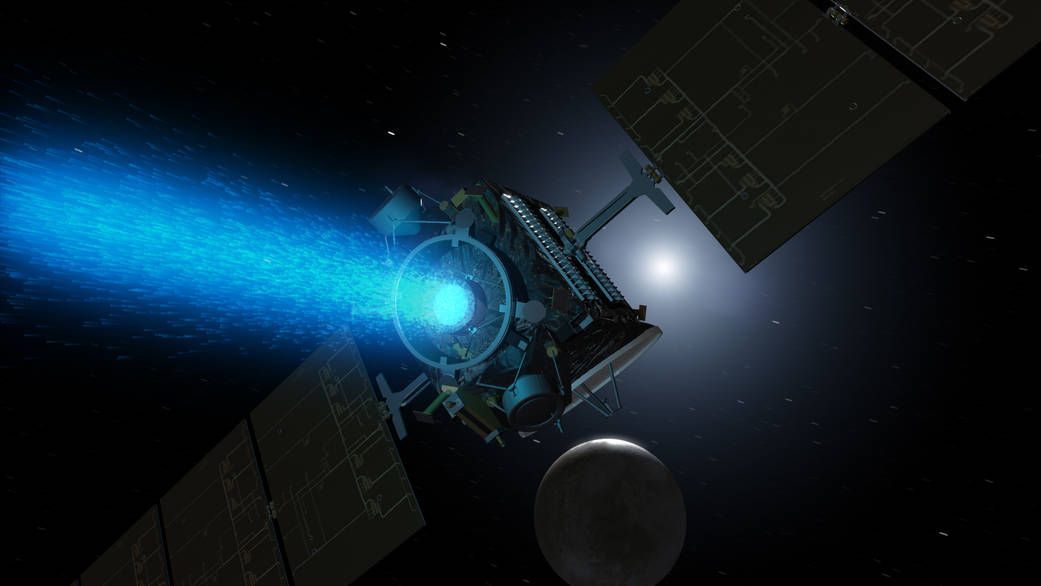

Our customers at Dynavac were crucial participants in a compelling project for NASA’s Magnetospheric Multiscale Mission at the Goddard Space Center. The Solar Terrestrial Probes mission were scheduled to fly four identically instrumented satellites to investigate how the sun and Earth’s magnetic fields transfer energy from one to the other. This transfer, called Magnetic Reconnection, affects space weather and by studying it, scientists at NASA gained the ability to observe how this process affects systems like communications networks, GPS navigation, and power grids back on Earth. Dynavac, an industry leader in the design and manufacture of thermal vacuum systems, supplied the project with aluminum cryopanel assemblies that allowed for thermal isolation of the satellites while they went through space simulation exercises in the lab prior to their journey in space. Each assembly was comprised of multiple panels joined together to form a thermally controlled and uniform test area. Aluminum extrusion was welded to each of the panels in a serpentine pattern which ultimately connected to stainless steel lines that delivered the liquids and gases to the assembly. Dynavac uses Atlas ATCR fittings to provide a compatible, demountable transition from the aluminum lines to their stainless-steel counterparts. Atlas has supplied Dynavac with thousands of ATCR fittings for the manufacture of their equipment.

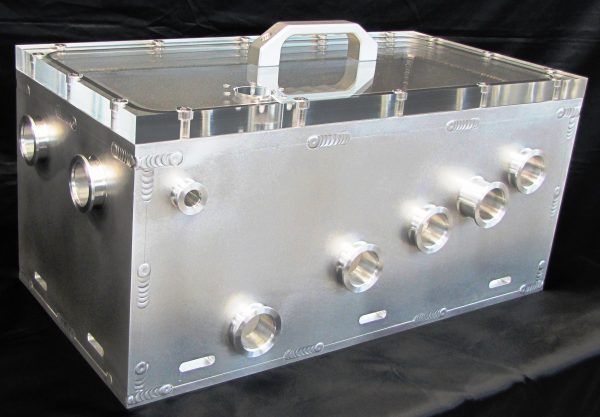

Several Atlas aluminum vacuum chambers with breadboards installed at Max Born in Berlin are used for the generation and application of ultra short x-ray pulses via a frequency conversion process called high order harmonic generation. The purpose is to record films of atoms and molecules on their natural time scales from the femtosecond (10^-15 seconds) to the attosecond (10^-18 seconds) range to capture atomic and molecular reactions. Reliable vacuum is essential to the process because the pulses absorb air. The rectangular shape and accompanying breadboard allows the team to strategically and simultaneously position several optical elements for ease of filtering and focusing on the x-ray pulses. This permits additional laser pulses, from the near-infrared to the ultraviolet regime, to overlap with the x-ray pulses in order to make the atomic and molecular recordings. Aluminum, says Dr. Bernd Schϋtte of Max Born, is the material of choice for the chambers because “it is cost effective and its low weight eases the handling of the chambers.”

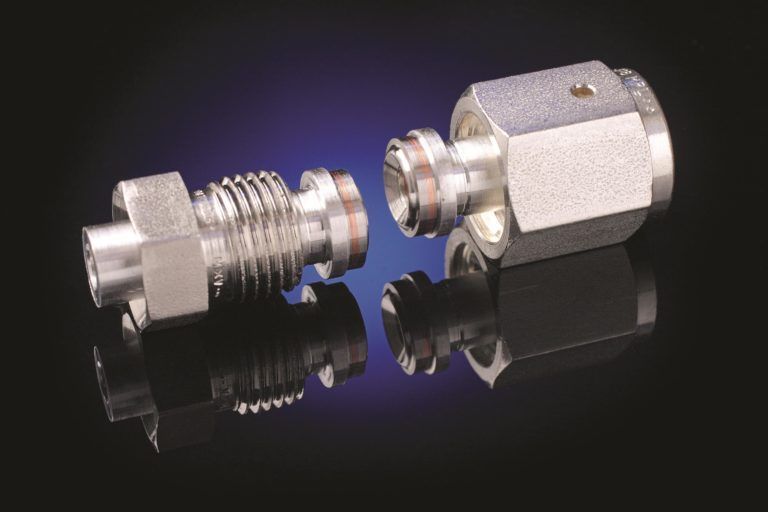

The Atlas ATCR™ Fitting – the aluminum tube fitting with a stainless steel face-seal offers a superior gas delivery system to cryogenic and semiconductor industries Industry leaders are taking advantage of the extensive benefits of aluminum in UHV to improve the performance of their most challenging applications in the fields of cryogenics, aerospace, physics, and semiconductors. For processes that require high thermal conductivity, light-weight materials, or chemical resistance aluminum delivers advanced functionality, and at a fraction of the cost. When comparing aluminum to stainless steel, aluminum is ten times more conductive, one-third the weight , and stands up to a variety of chemicals that trigger destructive corrosion on stainless steel surfaces. Other documented advantages of aluminum over stainless steel include low levels of outgassing, contamination, nuclear activation, and magnetic permeability, along with high vibration dampening. Additionally, aluminum provides superb machinabilty, space and weight reduction on site, and is lower in cost in terms of machining, shipping, and overall cost of ownership. Atlas ATCR™ fittings produce a robust, demountable use of aluminum tubing for some of the most demanding applications worldwide. These fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® fittings which makes incorporating Atlas ATCR™ fittings into existing stainless infrastructure uncomplicated. Standard socket, butt, male and chamber mount weld fitting geometries are available in 1/4, 3/8, 1/2, 3/4 and 1 inch tube diameters. Chamber mount fittings are available in four length configurations suitable for 1/2, 3/4, 1 and 1-1/4 inch chamber wall thicknesses. Atlas Socket, Butt and Male weld ATCR™ face-seal fittings are fitted with a durable stainless steel sealing face bonded to to an aluminum body. The bond produced is extremely rugged. All face-seal fittings are helium leak tested for service in UHV environments in excess of 1×10-9 Torr lt/sec He.

Aluminum Welding REFERENCE For Designers and Welders of Aluminum Ultra High Vacuum (UHV) Chambers Aluminum UHV Weld Design Most facilities familiar with Ultra High Vacuum (UHV) have experience welding stainless steel to UHV standards, however many have not had occasion to weld aluminum to UHV standards. We offer this brief guide for designing and welding aluminum chambers and Atlas Technologies’ aluminum/stainless bimetallic flanges and transitions to UHV standards. Similar Masses: We try to design weld geometries that have similar masses whenever possible. If there is a large difference between the mass of the chamber and the mass of a flange for example, this can cause frustration because the more massive chamber will tend to be cooler than the less massive flange and the flange will preferentially melt. If similar masses are not a possibility, oftentimes thermal chokes can be machined into the massive part, which constrain the heat loss. Also burying the less massive chamber in the massive flange will tend to spread the heat about in a more uniform manner. It is convenient to have V-grooves machined into aluminum weld joints. This permits liberal use of filler rod which reduces cracking. If joining tubes, the V grooves should be on the inside of the tube and penetrate ~2/3 the thickness of the wall. Cleanliness: Cleanliness is very important when welding aluminum. Make sure that the weld surfaces including the filler rods are freshly cleaned and fully dried. Even though aluminum forms an oxide instantaneously in air, a freshly cleaned surface with scotch bite can reduce the thickness and contamination present in that oxide. This is important because aluminum melts between 580-650 C, but its oxide melts at ~1760+C and is heavier than the aluminum alloy. Because of this, the oxide crust can sink into the molten weld and be a source of porosity. Preheating the aluminum: Because aluminum is such an excellent thermal conductor, vast amounts of heat are required when beginning a weld. As this heat spreads ahead of the weld bead, it accumulates in the part. This tends to reduce the amount of required heat during a weld. Rather than stopping and starting which are often areas for leaks, we recommend using a foot pedal current controller. During welding, stainless steel will glow red at its welding temperature; aluminum however will not. Aluminum will melt before it will glow. The welder must observe the melted weld puddle rather than the glow. Aluminum TIG Welding for UHV and Aluminum Atlas Flanges, Bimetallic Transitions Coupling and Fittings Welding Thick Aluminum for Vacuum Greater than 6mm + Thick (¼”): Max Bond Temp: Temperature at the bond should not exceed 300C. Keep a damp rag on the joint to prevent over heating during welding

Out gassed carbon from stainless steel can be a serious source of contamination and can damage synchrotron optics as well as deep Ultra Violet (DUV) and Extreme Ultra Violet (EUV) optics for semiconductor lithography. We are finding that many of these high profile labs are eliminating any potential carbon from stainless by using aluminum vacuum systems. Aluminum systems have essentially no carbon. The carbon from stainless also reacts with the elemental hydrogen and departs the surface in a variety of hydrocarbons. Additionally, CO and CO² are produced by the abundance of carbon from the stainless steel when reacting with oxygen. For some optical applications the vacuum level is less critical than the purity of the environment. This is typical in the semiconductor lithography market. Companies in this market are pulling UHV then backfilling with a pure gas and operating at relatively low vacuum but incredibly high purity levels: Ultra High Purity (UHP). Also in the semiconductor lithography market some manufactures are looking for the inside of their ultra high purity system to be anodized. The dark anodized skin reduces the reflectance off the chamber wall and provides for a more controlled optical environment. Atlas builds aluminum UHV and UHP chambers for synchrotron and semiconductor facilities seeking to eliminate these problems. Aluminum chambers can be sealed with rugged reliable Atlas flange joints which are aluminum flanges with a stainless knife-edge. These flanges permit aluminum vacuum chambers to offer superior UHV & UHP performance over stainless steel.

Atlas Technologies builds a non magnetic model of its Atlas FlangeTM, the aluminum flange with a stainless steel knife-edge and face using 316LN stainless. This alloy ensures a minimal magnetic permeability from the stainless steel while providing an aluminum base for weld-up to an aluminum chamber that is not magnetized during welding. The magnetic permeability of aluminum, near unity, and its excellent vacuum properties such as extremely high thermal conductivity, low H2 and no C content, light weight and low Z make aluminum a superior vacuum material for many UHV applications. See our section on aluminum vacuum properties for more information. Atlas also manufactures Atlas Flanges with hardened knife edges and faces using materials other than stainless. For example Atlas uses titanium instead of stainless as a knife edge material. This reduces the magnetic permeability even more than using 316LN and is ideal for extremely magnetically sensitive applications. Some non magnetic applications are better served with copper Ultra High Vacuum UHV chambers and flanges. Atlas manufactures custom copper chambers with hardened flanges surfaces to meet your specifications. Low permeability Atlas CF Flanges and chambers are in use at prominent national lab and accelerator facilities world wide. We would be delighted to talk with you about your application and assist you in the engineering and manufacture of flanges or chambers. Atlas Technologies offers low magnetic permeability stainless steel Ultra High Vacuum Atlas Flanges. These flanges enable you to apply the excellent extremely low permeability of aluminum through-out your vacuum system and still enjoy rugged stainless knifes with magnetic permeabilities far below conventional stainless steel. The low mu Atlas Flanges are carefully manufactured with atlas’ proprietary technologies yielding a very low permeability in the stainless around ~1.017 µ. Because aluminum has a lower mu than the low mu stainless and is less expensive, Atlas’ low mu flanges are the clear choice for low permeability vacuum applications. Atlas stocks low mu Atlas flanges: