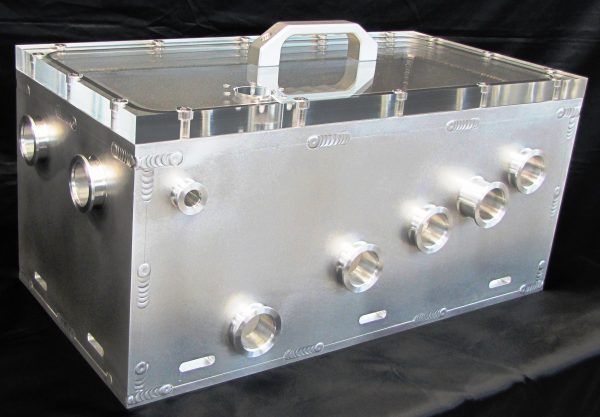

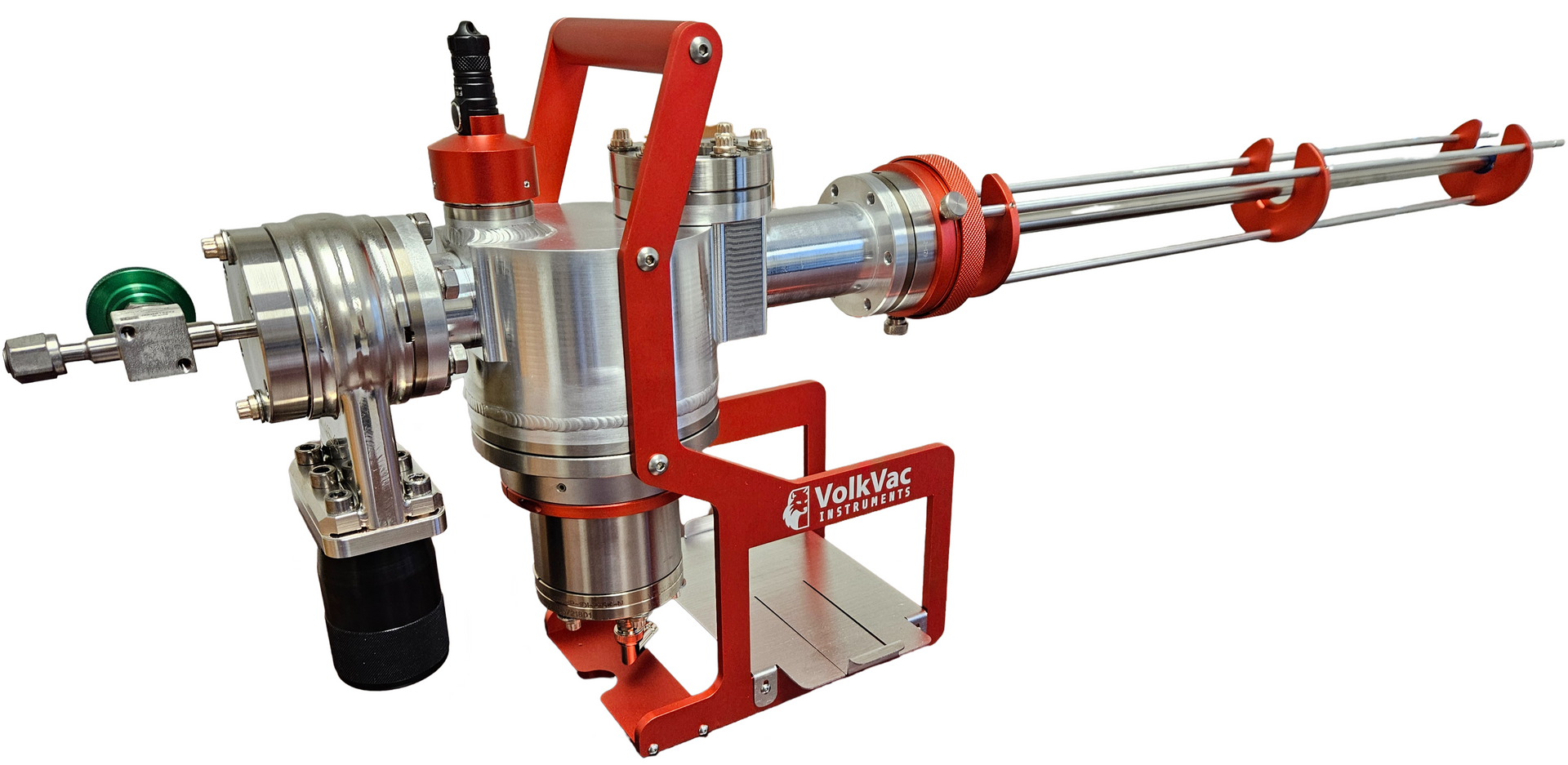

VolkVac Instruments teamed up with Atlas Technologies to develop lightweight UHV suitcases that are used to transport delicate samples long distances while under vacuum.

THE CHALLENGE:

Our customer, VolkVac Instruments, needed a UHV chamber small enough and light enough to easily carry by hand and that

could connect to another UHV chamber to allow transfer of samples under vacuum to a chamber in a new location. The sample handoff had to occur without opening the chambers or requiring bake-out. And the chamber had to be completely non-magnetic to allow transport of samples with delicate magnetic properties.

THE SOLUTION:

Atlas Technologies machined a vacuum chamber out of a single, solid block of aluminum for enhanced vacuum integrity. Then Atlas bimetal aluminum titanium flanges were welded to multiple ports of the chamber to allow connection to different vacuum systems. VolkVac fitted the chamber with passive and battery-powered vacuum pumps to maintain UHV pressure.

WHAT MAKES A UHV SUITCASE SO SPECIAL?

UHV suitcases solve a critical issue for researchers and others who need to move delicate samples from one ultra high vacuum (UHV) system to another without contamination or loss of vacuum pressure. Some UHV experiments are self-contained, but others require the cutting-edge analytical techniques available at large facilities such as synchrotrons, free-electron lasers and neutron sources.

Normally, fabricating a UHV sample in one place and studying it in another involves breaking the vacuum to remove and transport the sample. This creates two problems. First, exposing a sample to air may change or destroy its material properties. Second, the opened UHV chamber must be baked out before it can be used again — and a bakeout can take a few hours for an aluminum chamber, or several days for a stainless-steel chamber – significantly delaying critical projects.

These problems can be avoided by connecting a portable UHV system (called a UHV suitcase) to the main vacuum chamber and then transferring the sample into the UHV suitcase. The suitcase can then be used to move the sample down the hall, across campus, or around the world – where it can then be transferred to another UHV system.

PORTABLE UHV CHAMBERS FEATURE MULTIPLE PUMPS

VolkVac founder, PhD physicist Igor Pinchuk, explained further. “The idea of a UHV suitcase is not new. Researchers have been creating their own rough but workable solutions for decades”. The earliest iterations were simply standard vacuum chambers that were disconnected from one UHV system and then quickly wheeled to another — without being pumped.

This has changed in recent years with the arrival of new materials, vacuum pumps, pump controllers and batteries. It is now possible to create a lightweight, portable UHV chamber with a combination of passive and battery-powered pumps. Having an integrated pump is crucial because it is the only way to maintain a true UHV environment during transport.

Because pumps, controllers and batteries must be a part of each UHV suitcase, the material used to create the chamber of a UHV suitcase must be as light as possible to keep the overall weight to a minimum.

ALUMINUM UHV SUITCASES ARE ULTRALIGHT AND NON-MAGNETIC TOO

While commercial designs have improved significantly over the past two decades, many UHV suitcases are still heavy and

unwieldy. To address these shortcomings, VolkVac Instruments developed the ULSC ultralight aluminum suitcase, which weighs

less than 10 kg, and an even lighter version – the ULSC-R –which weighs in at less than 7 kg.

The use of a custom Atlas aluminum chamber with bimetal aluminum-titanium flanges is integral to the success of VolkVac’s

UHV suitcases. Aluminum was used instead of stainless steel, another common chamber material, as aluminum is lighter and

much easier to machine. The chambers for the UHV suitcases were efficiently machined from a single piece of aluminum for

increased integrity. The lightweight material is also non-magnetic. This allows the suitcases to be used to transport samples with

delicate magnetic properties.

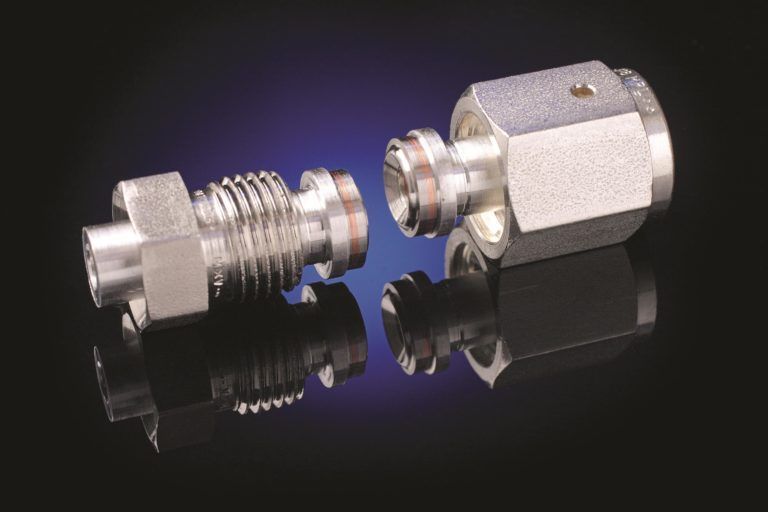

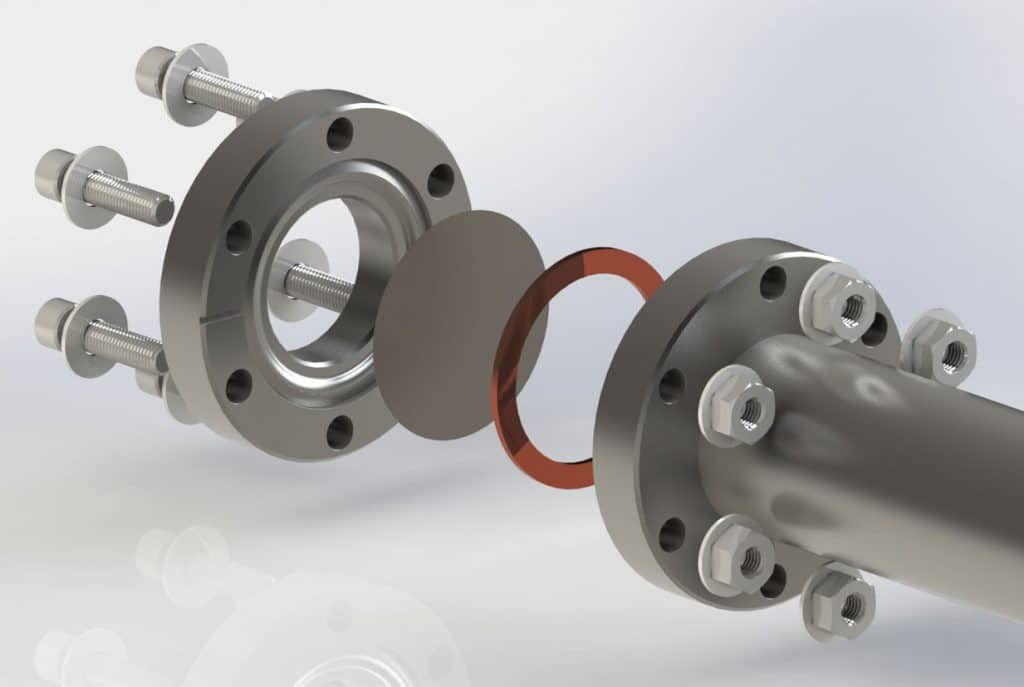

BIMETAL ALUMINUM/TITANIUM FLANGES COMPLETE THE CHAMBER

Access to UHV chambers is provided by conflat (CF) flanges which have sharp edges that are driven into a copper-ring gasket to create an exceptionally airtight seal. While aluminum is the best material for making UHV suitcase chambers, it is too soft to provide durable long-lasting sharp knife edges on flanges. That’s why VolkVac came to Atlas Technologies — our expertise in dissimilar metal bonding and fabrication as well as aluminum chamber development. Atlas fabricated the aluminum flanges with titanium knife-edges. Using aluminum and titanium ensured that the suitcases would be non-magnetic as well as lightweight.

ATLAS AND VOLKVAC WORKED CLOSELY TO OPTIMIZE THE NEW SUITCASES

Jimmy Stewart, Technical Sales Manager at Atlas, coordinated the collaboration with VolkVac. Jimmy explained that VolkVac

continues to work very closely with Atlas’s lead machinist and lead engineer to develop the suitcase chambers. Several chambers

have now been manufactured, with more in the works. Stewart said “This close relationship is necessary because bimetal materials have special requirements when it comes to welding and stress relief. We often work like this with our customers across various industries to produce the specialized equipment they require.”

“Because of the historical use of stainless steel in UHV systems, some customers are unfamiliar with bimetal components. They may have heard about the benefits of bimetal,” says Stewart, “but they don’t have the expertise. And that’s why they come to us — for our 30 years of experience and in-depth knowledge of bimetal and aluminum vacuum.” Pinchuk agrees. “I know stainless steel UHV technology forwards and backwards, but now I’m benefitting from Atlas’s expertise in aluminum chambers and bimetal

technology for my latest products.”