Two metal rings with holes in them on a white background

Two metal rings with holes in them on a white backgroundTwo metal rings with holes in them on a white background

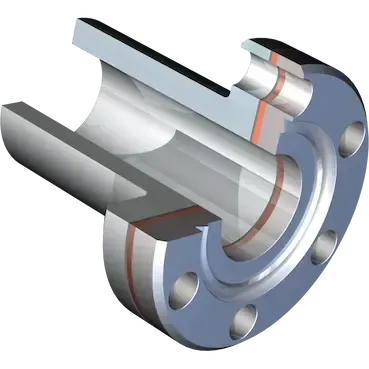

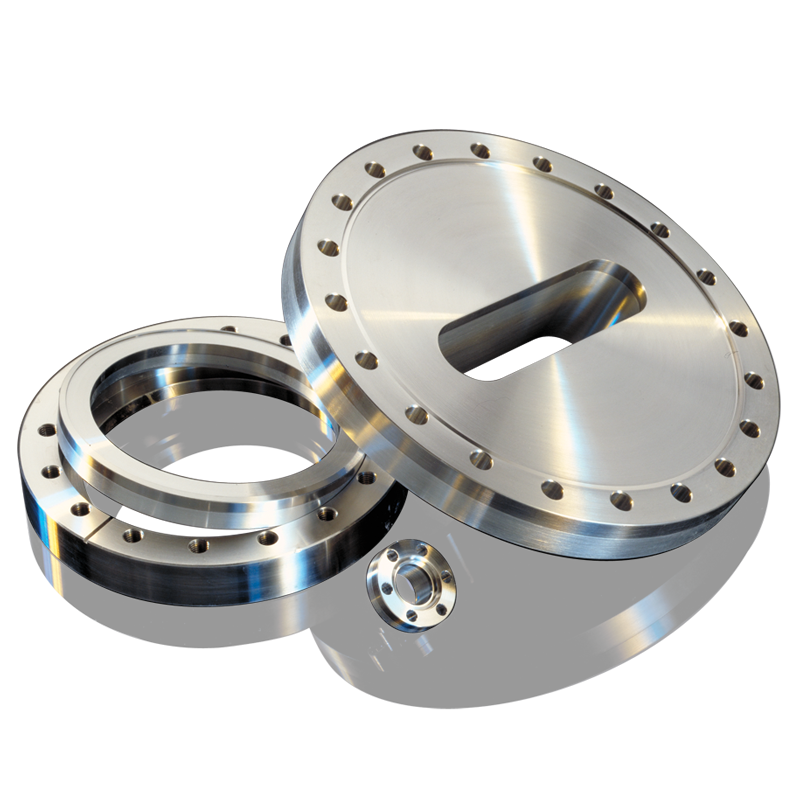

Bimetal Al/SS CF Flanges

All-metal sealing for aluminum vacuum

The Atlas Bimetal Al/SS CF Flange—the aluminum flange with a stainless-steel knife-edge seal— offers all-metal sealing and weld-up to aluminum chambers

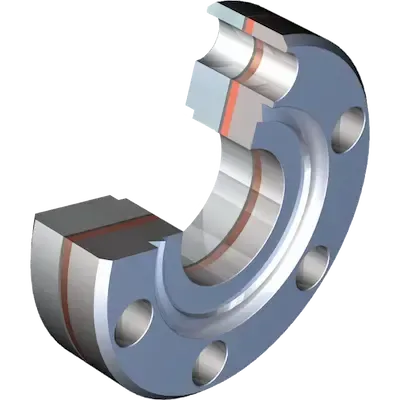

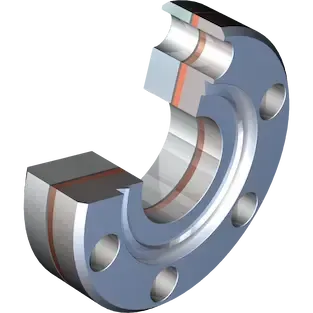

Rotation

Bolt Holes

Bore

2.75" (70mm/DN40) tube mount bimetal Al/SS CF flange

Bimetal flanges and fittings typically ship in 4-5 weeks. Please contact us to check inventory or inquire about expediting your order.

Online orders are available for US and Canada only. Prices will differ in other regions.

Contact your local sales team for more information

Product Specifications

Atlas Bimetal Al/SS CF Flanges allow vacuum engineers and designers to fully utilize the exceptional vacuum properties of aluminum in UHV and lower vacuum applications. In applications where superior heat conduction, chemical resistance, manufacturing ease, and lower cost are paramount, aluminum vacuum chambers using bimetal flanges offer measurable productivity and cost-of-ownership advantages.

Applications

Low-Magnetic: Aluminum vacuum chambers using Atlas bimetallic flanges are ideal for applications requiring non-magnetic materials:

- Synchrotron

- Particle physics

- Industrial applications

Low Z, Low Nuclear Activation: In applications such as the production of radioisotopes for medical imaging, aluminum vessels fitted with Atlas bimetal flanges replace all-stainless steel UHV systems. Residual, neutron-induced radiation in aluminum has a half-life that is orders of magnitude shorter than that of stainless steel (which contains cobalt and chrome), This enables use in applications such as:

- Cyclotrons

- Nuclear reactors

- Medical Imaging

Light/Low Weight: Ideal for weight sensitive applications, at 1/3 the weight of stainless steel, aluminum chambers offer smaller footprints, reduced shipping costs, and faster installation times. Bimetal flanges offer a simple, effective transition from aluminum chamber to stainless steel systems.

- Aerospace

- Portable systems

Features & Specifications

- UHV Rated to 1×10 -13+ Torr

- Bake-out temperatures up to 250°C

- Fully compatible with industry standard ConFlat flange interface – CERN’s innovative 20° back-bevel (90° included angle) knife-edge design

- Provides a longer service life than conventional CF flanges

- Standard flange sizes: 1.33”-16.5” (DN16-DN500)

- Used in high (HV), ultrahigh (UHV) and extreme high vacuum (XHV) applications

- Cryogenic, non-magnetic, rectangular and other specialty flange solutions also available

- Custom flanges with a reduced cross section are available to reduce overall weight

Materials

- Body/weld interface: aluminum 6061-T6

- Sealing knife-edge face: stainless steel 316L

- Rotatable collar/receiver: aluminum 6061-T6

Environmental

- Vacuum leak tested: < 1 x 10-9 cc/sec of He

Thermal

- Peak temperature: 300°C (during weld-up) See our aluminum weld guide PDF

- Operational temperature: -200°C to 250°C

Mechanical—Bonded Interface

- Tensile: 15,00psi (103MPa)

- Shear: 10,000psi (69MPa)