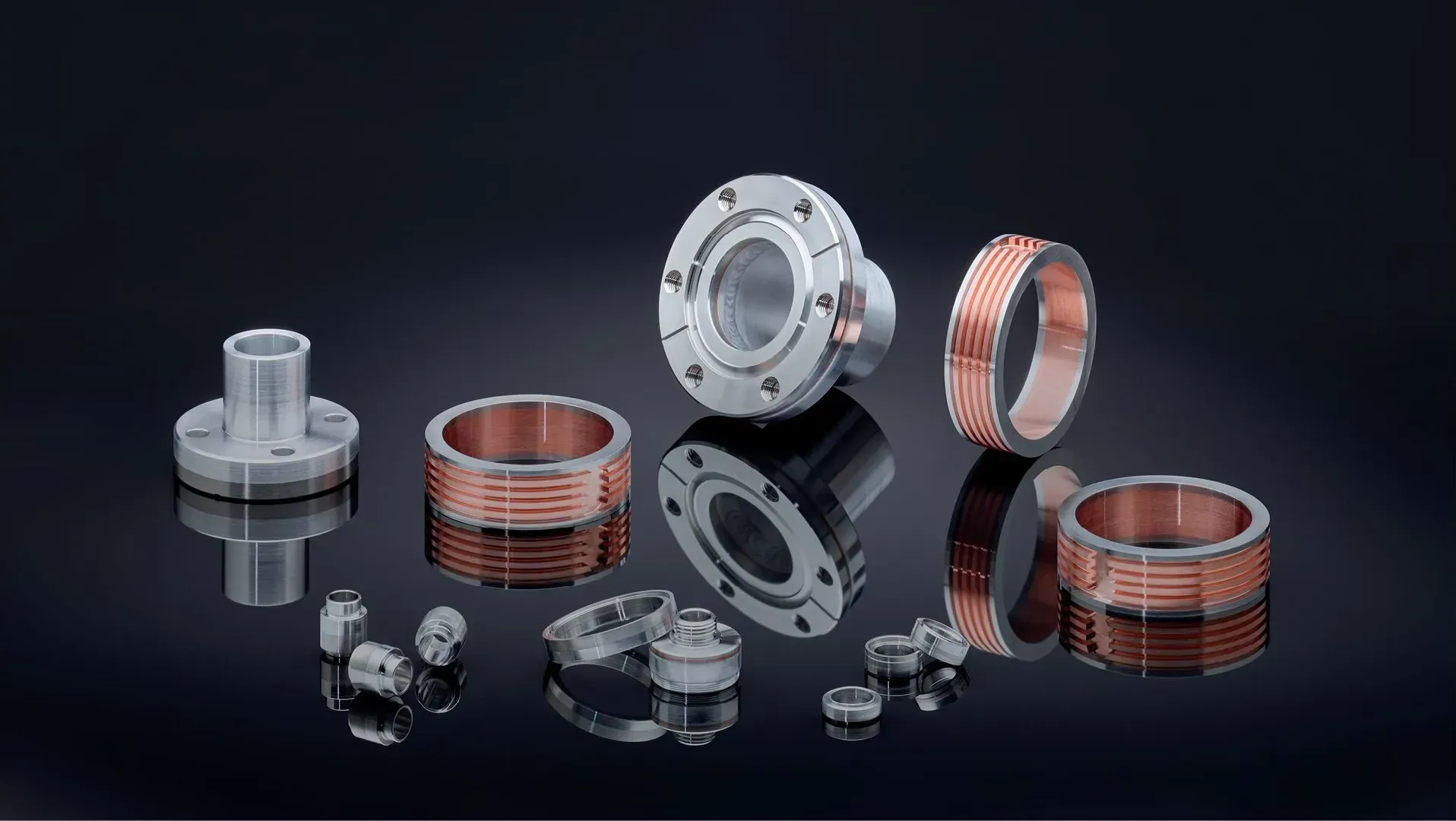

DISSIMILAR METAL PRODUCTS

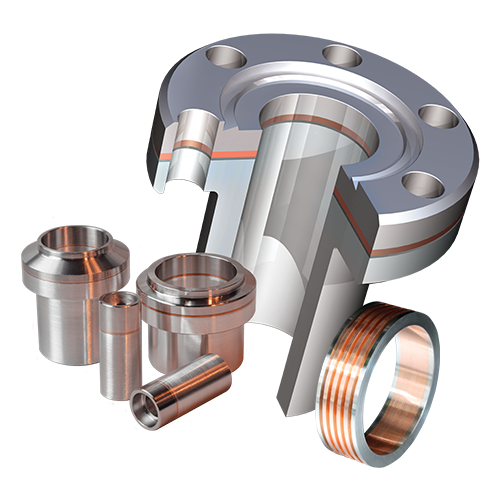

Atlas dissimilar metal bonds are mechanically robust, totally hermetic, and remain ductile in pyrolytic or cryogenic temperatures. With solid-state explosion bonding, diffusion bonding, and roll bonding, a huge variety of metals can be joined and can then be further machined and welded to adjacent metals.

The bonds are so strong and reliable, they are used in Ultra High Vacuum (UHV) and Extreme High Vacuum (XHV) applications for the semiconductor, chemical processing, cryogenics, aerospace, and particle physics industries where even infinitesimal porosity or leakage is intolerable.

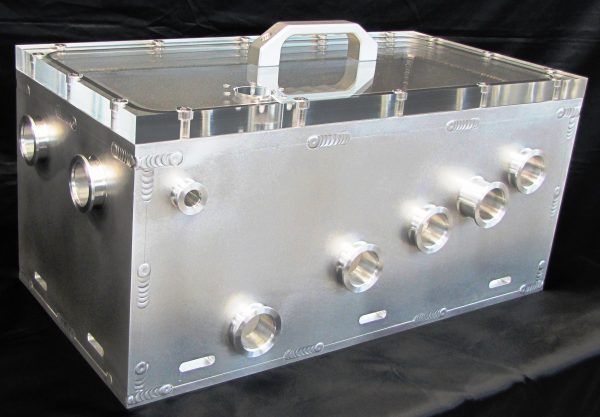

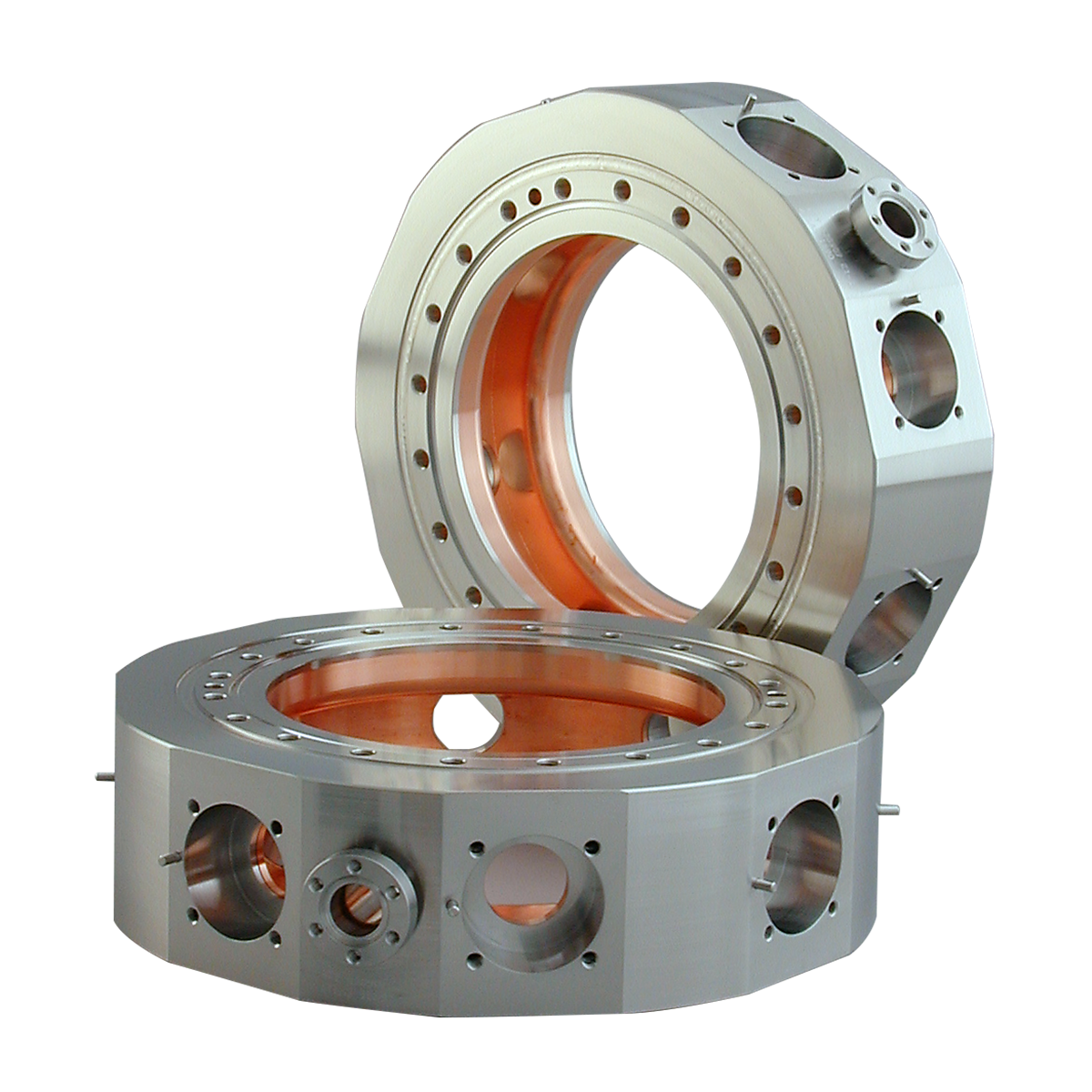

CUSTOM VACUUM CHAMBERS

We thoroughly understand the vacuum and manufacturing subtleties in making aluminum, titanium and copper chambers. We are eager to assist you in applying this knowledge toward your specific application. Our passion for materials will help you obtain the performance you are looking for.

Because of our dissimilar metal bonding experience, we approach vacuum material usage with an open mind. We are able to circumvent many welding or joining issues and can apply a wide variety of materials and material conditions precisely where they are needed.

DESIGN • DEVELOP • MANUFACTURE • SUPPORT

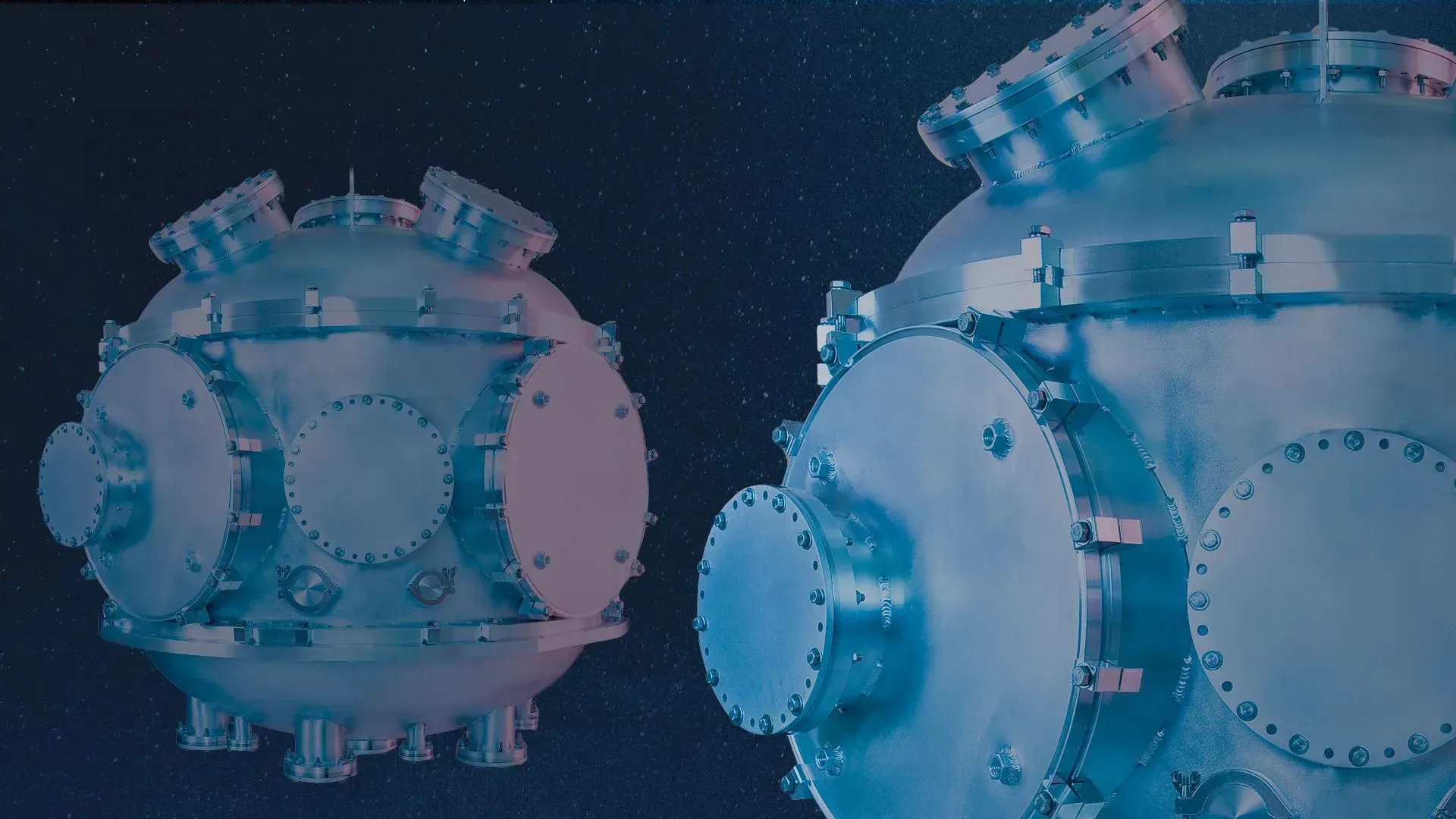

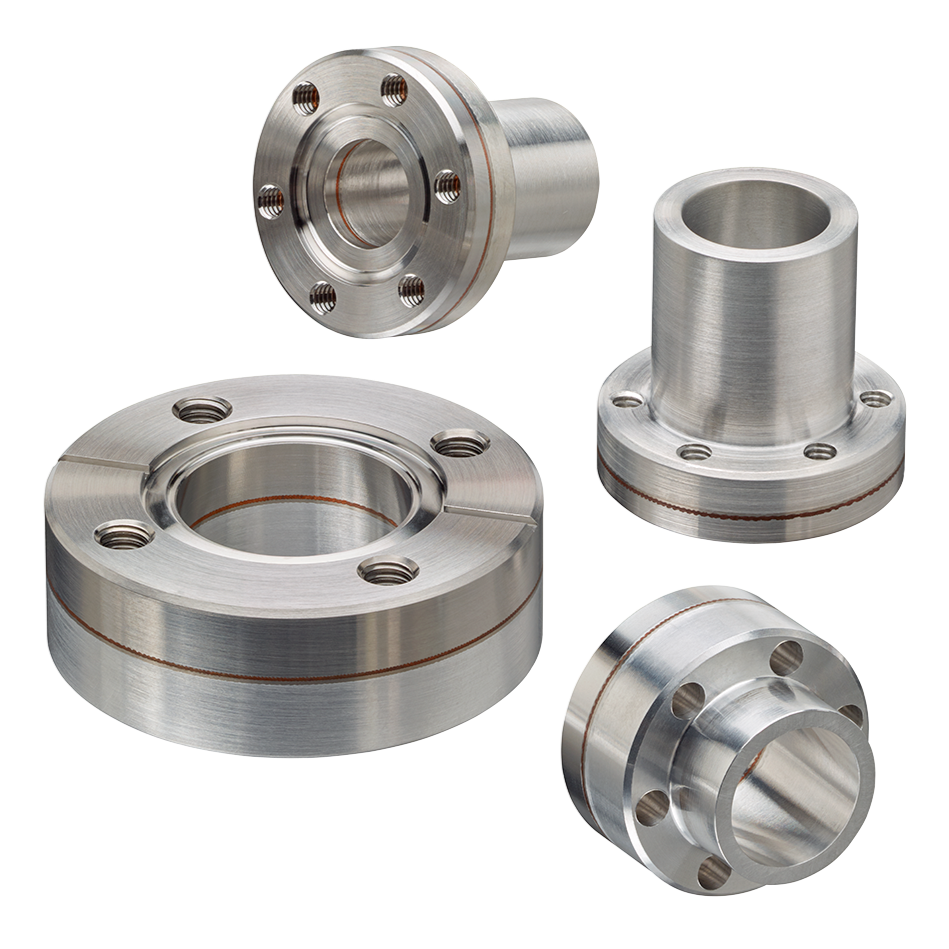

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a rough sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.

WHAT OUR CUSTOMERS SAY

WHY ATLAS?

Experienced Problem Solvers

For over 20 years, Atlas Technologies’ Enhanced Vacuum Technology Products and Services have helped lead the aluminum ultra-high vacuum revolution. We love to develop new products that better serve you, our customers.

Precision Products, High-Performance Materials

Our bimetallic technology often allows us to solve some of your most difficult challenges and help you think about your project with more options than just stainless steel.

Expertly-Crafted Solutions Made in the USA

Our inventions give innovators the tools to advance energy, space, medicine, physics, quantum computing, and commodity preservation. All crafted in the USA.

Satisfied Customers

We’re proud to contribute to the success of thousands of leading edge customers from some of the most prestigious institutions around the world.

leading-edge Products

ATLAS NEWS AND ARTICLES