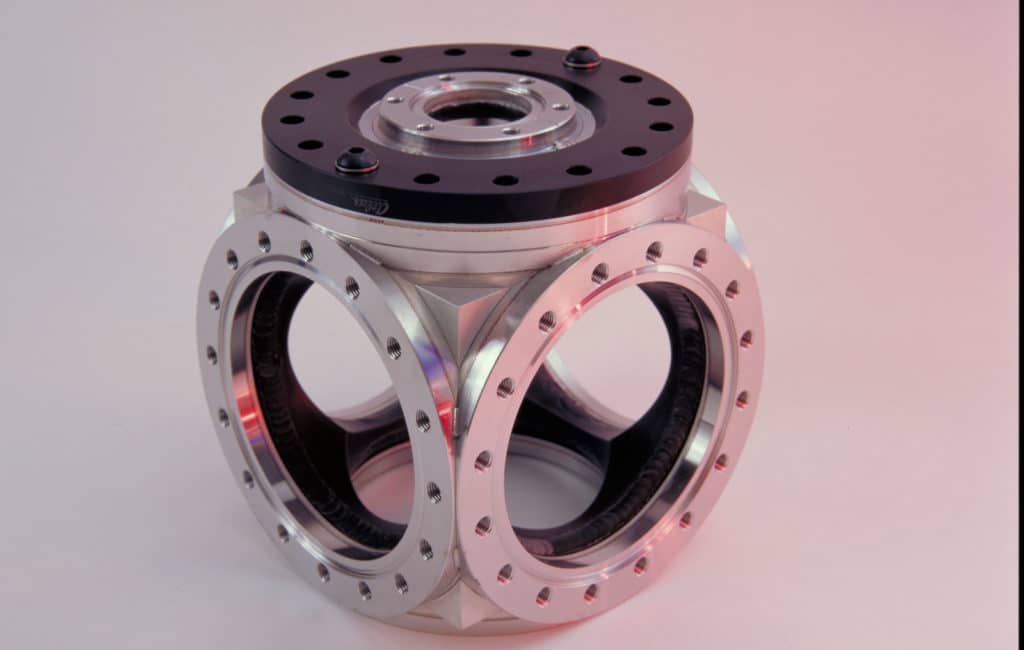

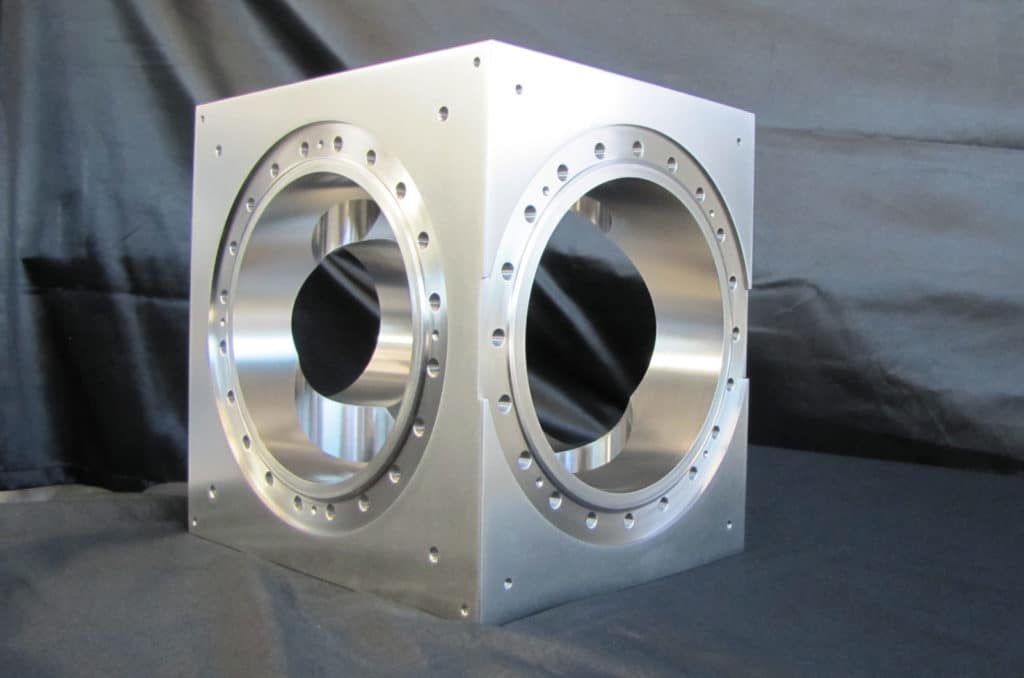

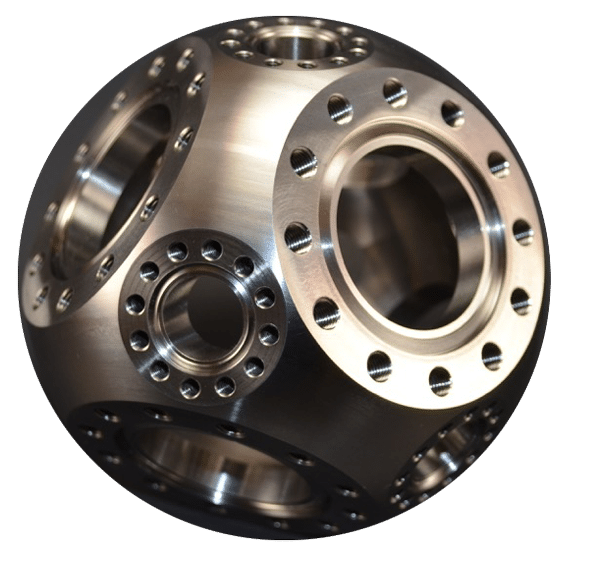

Please contact us to learn more! Atlas has considerable experience in building vacuum chambers from low vacuum to UHV and XHV (1 x 10-13+ Torr).

Contact us now

High-Performing Materials

There are many material factors that interact to create a more efficient vacuum chamber design. Material properties such as gas permeability (particularly hydrogen), surface oxide condition, density, innate vapor pressure, grain size, magnetic permeability, and many other properties have a significant impact on vacuum performance.

We LOVE materials! Countless design opportunities open up when you understand and apply materials science effectively.

We thoroughly understand the vacuum and manufacturing subtitles in making aluminum, titanium and copper chambers. We are eager to assist you in applying this knowledge towards your specific application. Our passion for materials will help you obtain the performance you are looking for.

Advanced Materials Joining:

Because of our dissimilar metal bonding experience, we approach vacuum material usage with an open mind. We are able to circumvent many welding or joining issues and can apply a wide variety of materials and material conditions precisely where they are needed.

Gas permeability, hydrogen, and stainless steel… a dirty secret:

Aluminum, titanium, and copper tend to prevent hydrogen mobility, but for stainless steel this is NOT the case. Hydrogen is a leading contaminate in stainless vacuum systems, due in part to the high solubility of hydrogen in stainless. This is exacerbated by the stainless steel refining process where hydrogen furnaces infuse the stainless with high levels of hydrogen.

Aluminum and titanium each interact with hydrogen differently. Due to its low solubility and dense oxide (Al2O3) surface layer, aluminum has very low hydrogen permeation. Titanium chemically reacts with hydrogen, trapping it within the metal (essentially acting as a getter pump). Most vacuum chamber manufacturers are reluctant to stray from conventional material choices and still exclusively use stainless steel. Atlas is committed to applying our expertise in material sciences to usher in the aluminum and titanium vacuum chamber revolution!