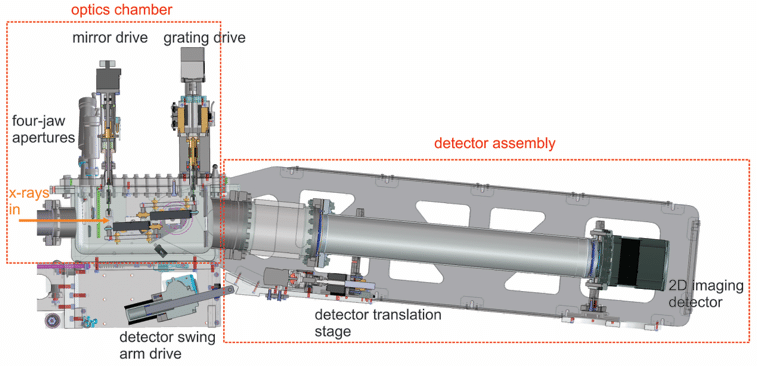

The Detector Assembly:

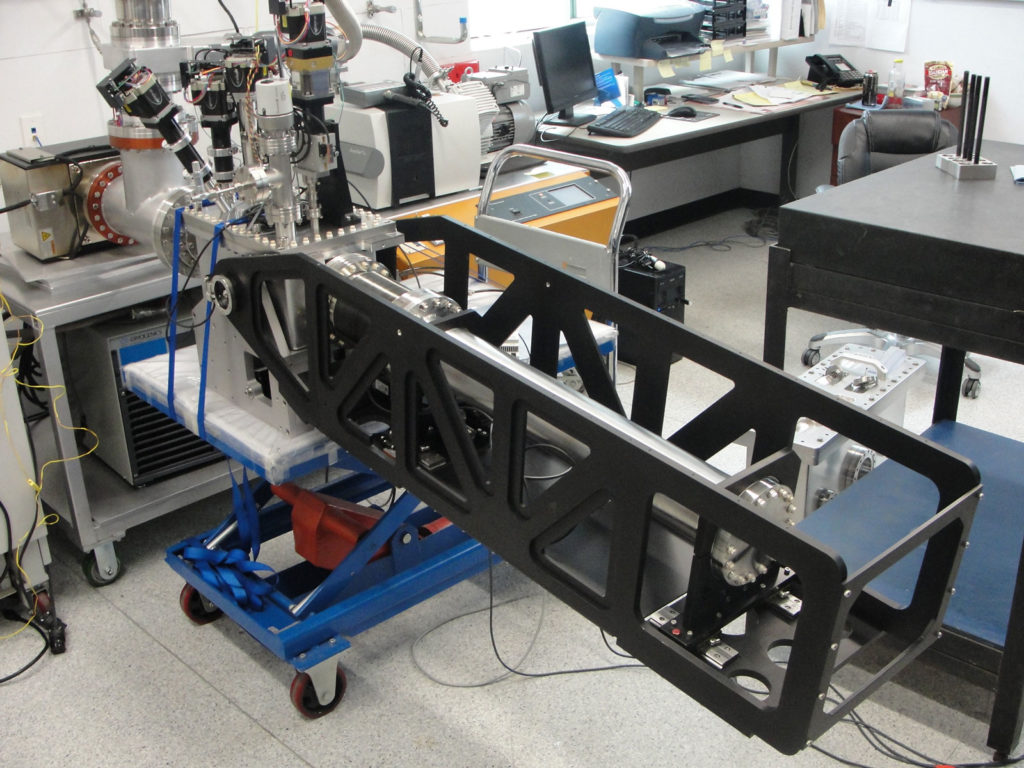

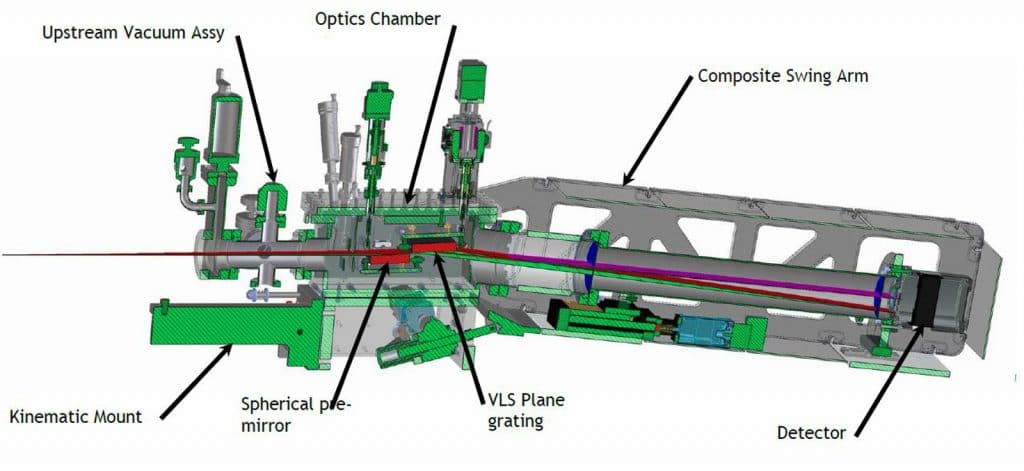

Held inside a light-weight aluminum swing arm, a fly tube holds the 2D imaging detector mounted on the tube that is connected to the optics chamber by a large bellows. The bellows allows the detector angle and position to be changed while maintaining ultra-high vacuum (UHV). The swing-arm fly tube assembly is supported by the brackets mounted on top of two translation stages, which in turn are driven by a motorized jack to change the detector angle relative to the horizon and move the detector along the optical path. This degree of freedom changes the distance between grating and detector, which is needed to correct for defocusing when MXS is recording photon energies far away from the nominal photon energy.

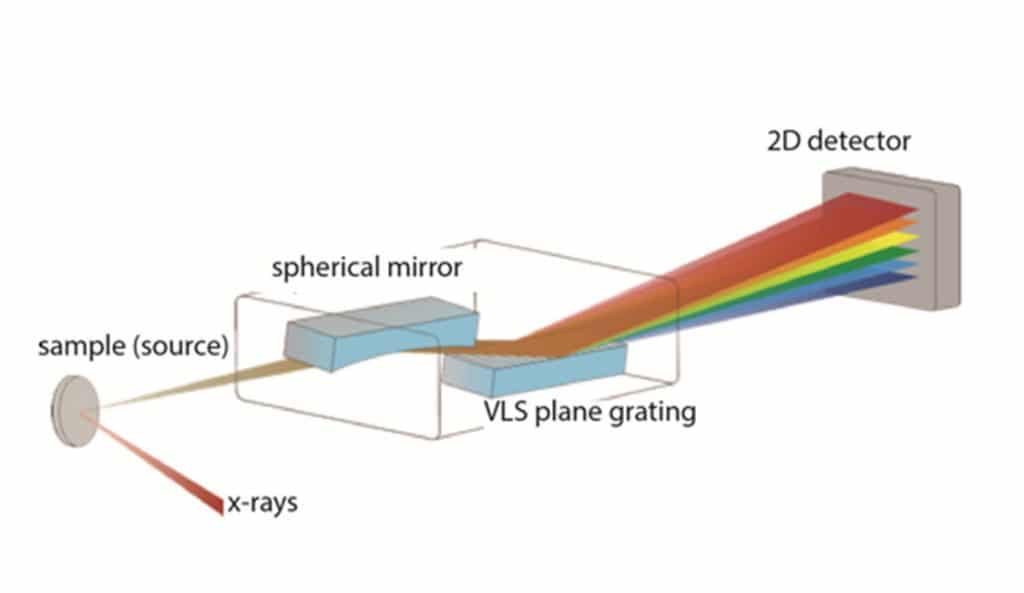

To detect x-rays with different photon energy during the measurements, one only needs to change the detector angle and the distance between grating and detector to correct for defocusing.

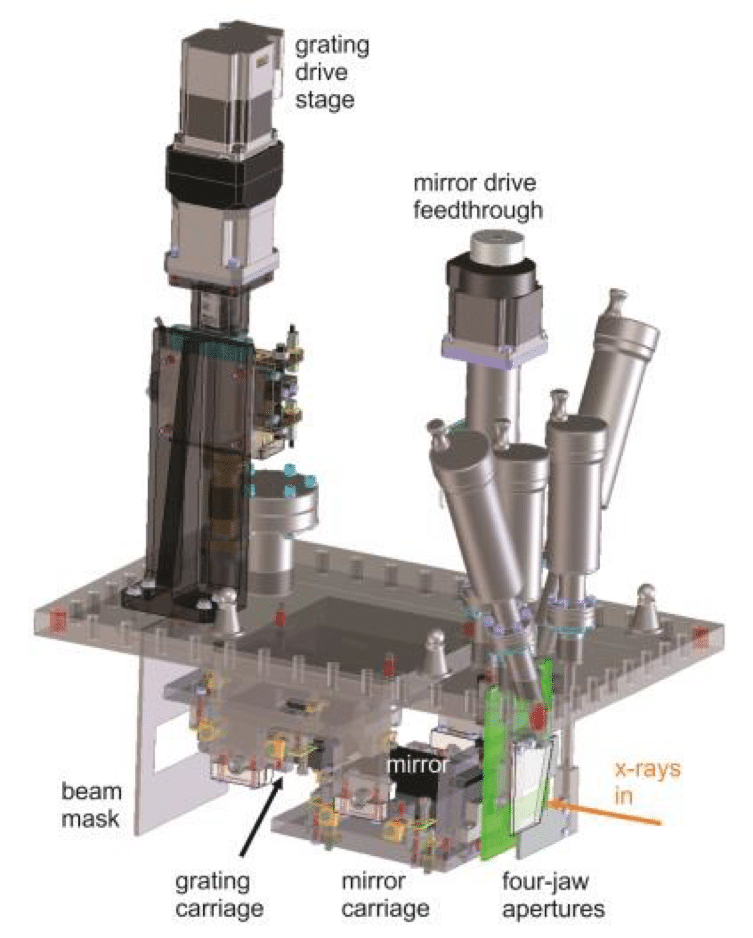

Comparing Scientia model XES-350 to the Atlas MXS-qRIX-1000 Soft X-Ray Grating Based Spectrometer, ours has a resolving power of 1,000~5,000 (0.05eV ~ 0.2eV). The MXS can use all types of gratings, whether constant line spacing or varied line spacing, with different surface figures; such as planar, spherical or even elliptical. Different types of gratings can have their respective strengths and limitations. Being able to choose gratings freely with MXS will offer the optical designer the freedom to select ideal optical parameters.

On the other hand, XES 350 can only use fixed radius, constant line spacing, spherical gratings. Although such gratings were easier and less expensive to produce decades ago, they cost almost the same as other types of gratings these days, thanks to the advanced grating fabrication technology. MXS has a far more advanced design that takes full advantage of the latest grating fabrication technology.