Bimetal Tube & Pipe Couplings

Standard Tube and Pipe Bimetallic (Al/SS) Transition Couplings

To add this product to your quote cart or for CAD file access, please login or create an account.

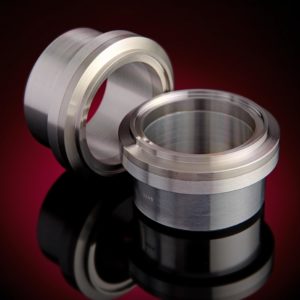

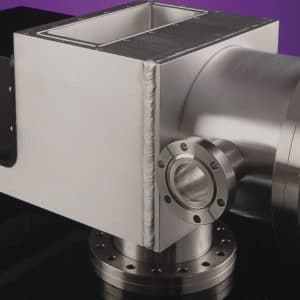

Atlas bimetallic transition couplings are robust, metallurgically-bonded dissimilar metal joints used to weld dissimilar metal tubes or pipes. These high strength joints are reliable and engineered to withstand typical welding temperatures. They are hermetic and suitable for use in Ultra High Vacuum (UHV) and are used in thousands of cryogenic and industrial applications worldwide.

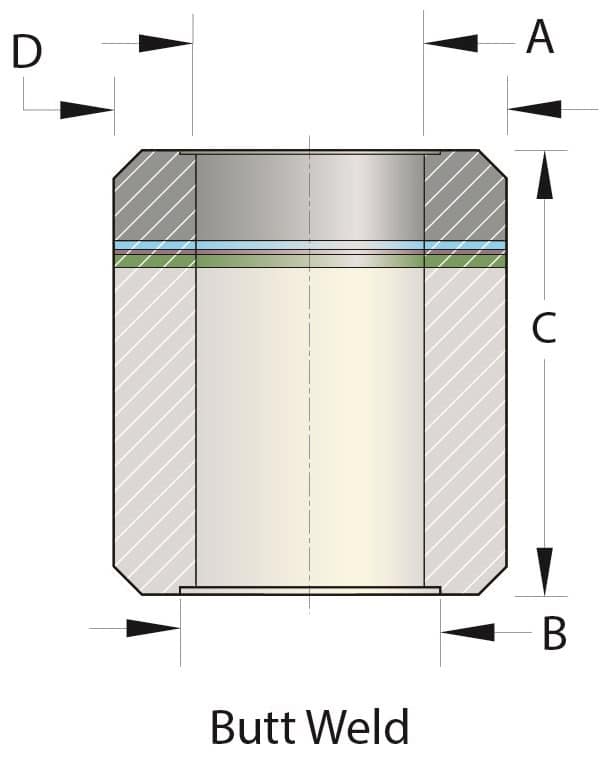

Diagrams & Variations

Related Content

-

Standard Line of Bimetallic Transition Couplings

Atlas Technologies Introduces Standard Line of Robust Bimetallic Transition Couplings Standard sized aluminum to stainless bimetallic transitions allow aluminum tube or pipe to be welded directly to stainless steel tube or pipe Atlas bimetallic couplings allow for a clean no-flange transition from aluminum to stainless steel tubes or pipe lines. These joints are highly reliable and … Continued

-

Why Aluminum?

The Aluminum Advantage Industry leaders at Atlas allow you to take full advantage of the benefits of aluminum over stainless steel: 10x the thermal conductivity and 21 x the thermal diffusivity for fast, complete bakeouts and unmatched thermal performance 7 orders of magnitude less hydrogen for ultra pure vacuum Less carbon for reduced contamination Outgassing … Continued

-

Aluminum Welding

Welding Reference Information for Designers and Welders of Aluminum Ultra High Vacuum (UHV) Chambers Aluminum UHV Weld Design Most facilities familiar with Ultra High Vacuum (UHV) have experience welding stainless steel to UHV standards; however, many have not had occasion to weld aluminum to UHV standards. We offer this brief guide for designing and welding … Continued