Atlas All Titanium Fittings, Ti-CR

To add this product to your quote cart or for CAD file access, please login or create an account.

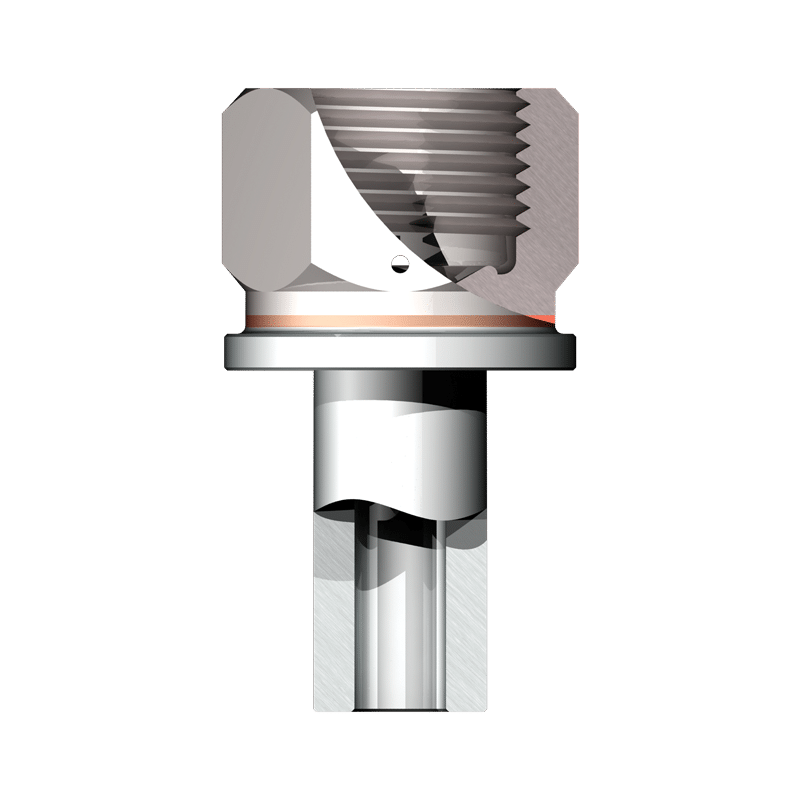

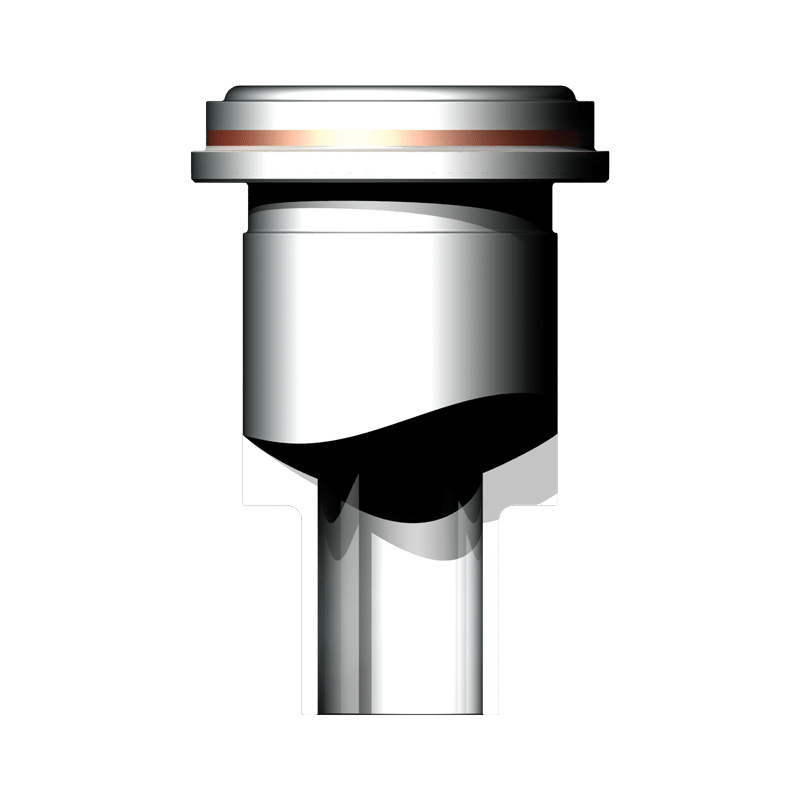

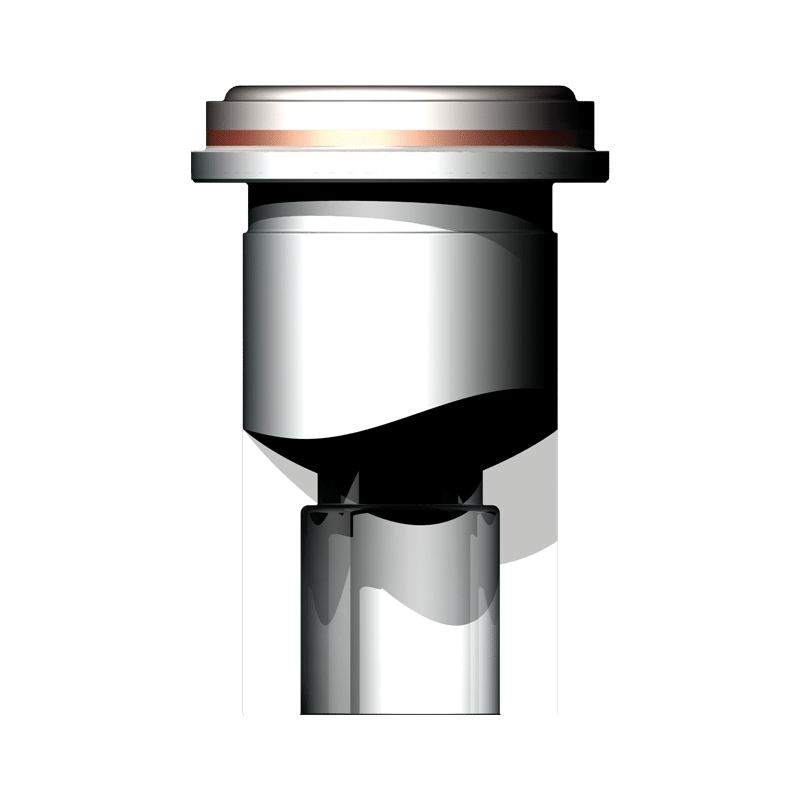

Atlas all-titanium Socket Weld, Butt Weld, and Male Weld Ti-CR™ face-seal fittings are extremely durable and exemplify the best in sealing technology. Atlas Ti-CR™ fittings enable robust, demountable sealing with titanium tubing in cryogenic, physics and semiconductor applications. Standard fittings geometries are available in ¼”, 3/8”, ½”, ¾” and 1” inch titanium tube diameters. Atlas Ti-CR™ fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® fittings and are used where light weight and the high chemical resistance properties of titanium are required.

Atlas Ti-CR™ Titanium face-seals offer a solution for gas delivery systems in the cryogenic and semiconductor industries and are the ideal choice for UHV and XHV environments.

Atlas Ti-CR™ fittings make titanium vacuum processing a reality.

Specifications:

Atlas Ti-CR™ face-seal fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® fittings.

Materials:

- Body and Face-Seal Interface: Grade 2 Titanium

- Rotatable Nut: Stainless Steel 304, Titanium Grade 2

Environmental:

- Vacuum: Leak tested to < 1 x 10-9 cc/sec of He

Thermal

- Bake-out: 450ºC

- Operational Temperature: – 400ºC to 400ºC

Mechanical (EXW Interface):

- Tensile: >15,000psi

- Shear: >10,000psi

Applications:

- Used in cryogenic feed lines

- Used in aerospace

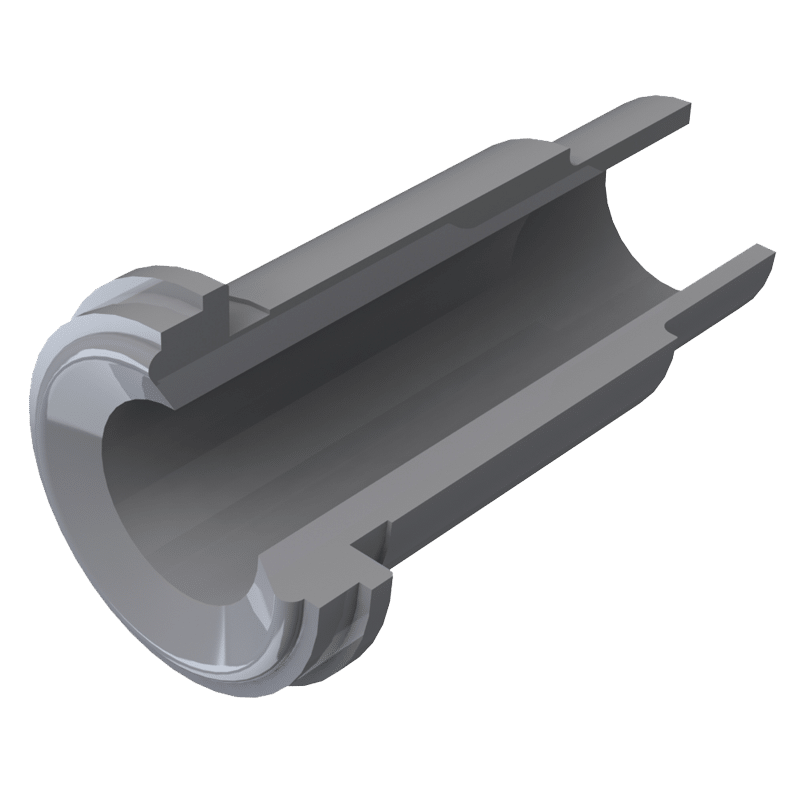

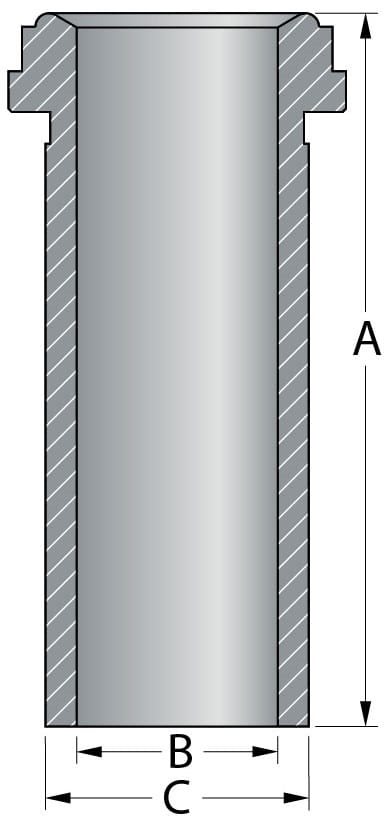

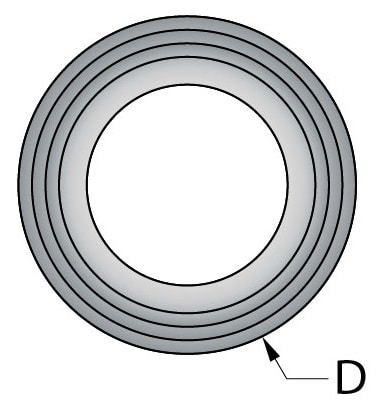

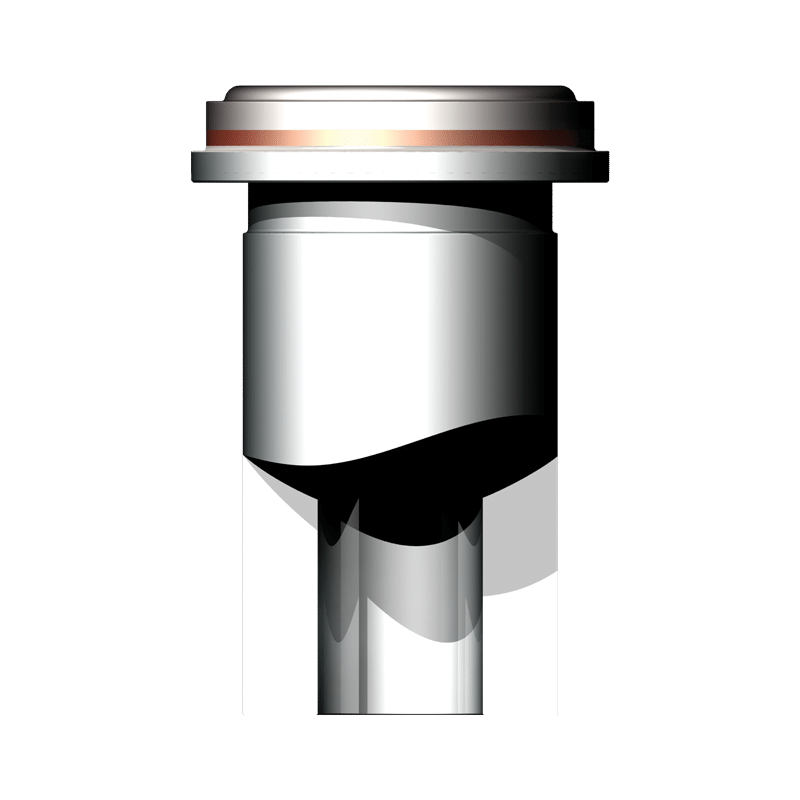

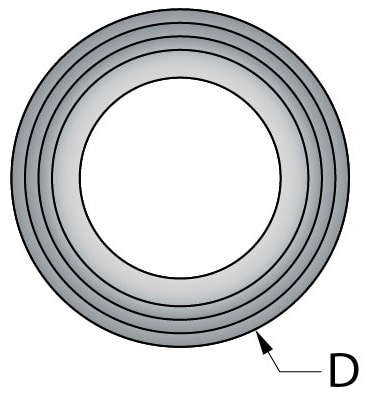

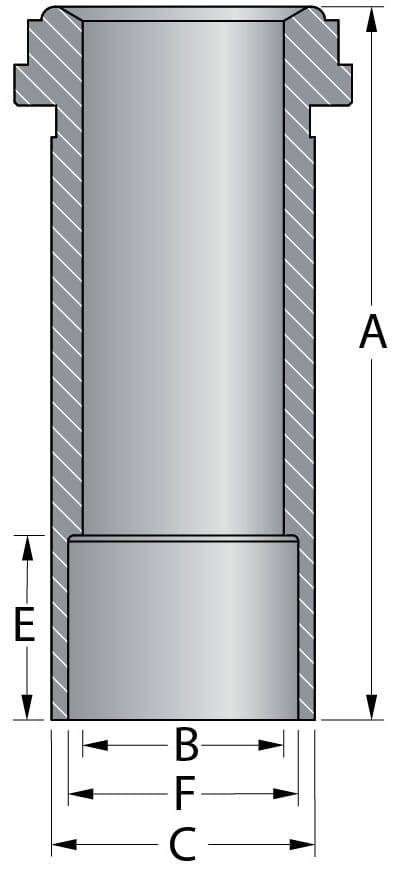

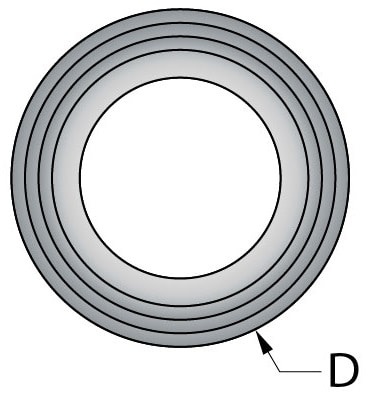

Diagrams & Variations

Related Content

-

Better Vacuum News Vol. 1 Issue 2

In this edition of Better Vacuum News you’ll find information about loadlock and optics chambers, why titanium is the best choice for XHV, the successes of some of our customers, and new products Atlas Technologies – Better Vacuum Newsletter Vol. 1 Issue 2 Source Url: http://blog.atlasuhv.com/?p=171

-

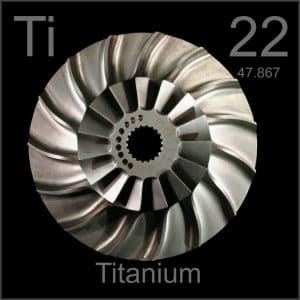

Titanium: a superior material for XHV

Atlas titanium chambers offer extreme vacuum performance with very low hydrogen permeation rates and secondary gasses. Due to the gettering properties of this metal, titanium vacuum chambers are, in many ways, the ultimate vacuum material. For extreme high vacuum, titanium will often be the best choice. But, due to cost of the material and the … Continued

-

Why Titanium

Like aluminum, titanium offers advantages that Atlas utilizes to manufacture the most effective solutions possible for your application: • Once activated, behaves as a getter to absorb hydrogen • Low thermal conductivity • No hydrogen for ultra pure vacuum • No carbon for greatly reduced contamination • Low thermal expansion • Non magnetic for applications … Continued