Titanium Vacuum Innovation

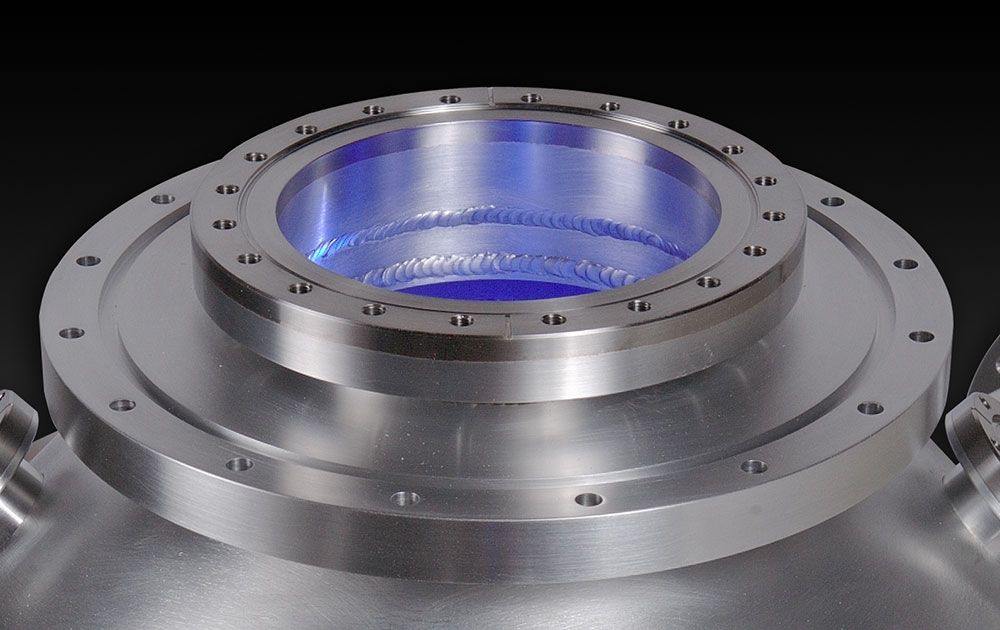

Atlas titanium chambers offer extreme high vacuum (XHV) performance with very low hydrogen permeation rates and minimal secondary gas contamination.

Titanium: a superior material for XHV:

For extreme high vacuum (XHV), titanium will often be the best choice. Due to cost of the material and the slow machining capabilities, it is typically used only when extreme high vacuum is required.

Applications that may require XHV:

- X-Ray Lithography

- Particle Physics

- Accelerators

- Cryogenics

- Non-Magnetic Environments

Customers using our titanium products include government institutions, universities, accelerator labs, and manufacturers in the semiconductor, quantum computing, and aerospace industries.

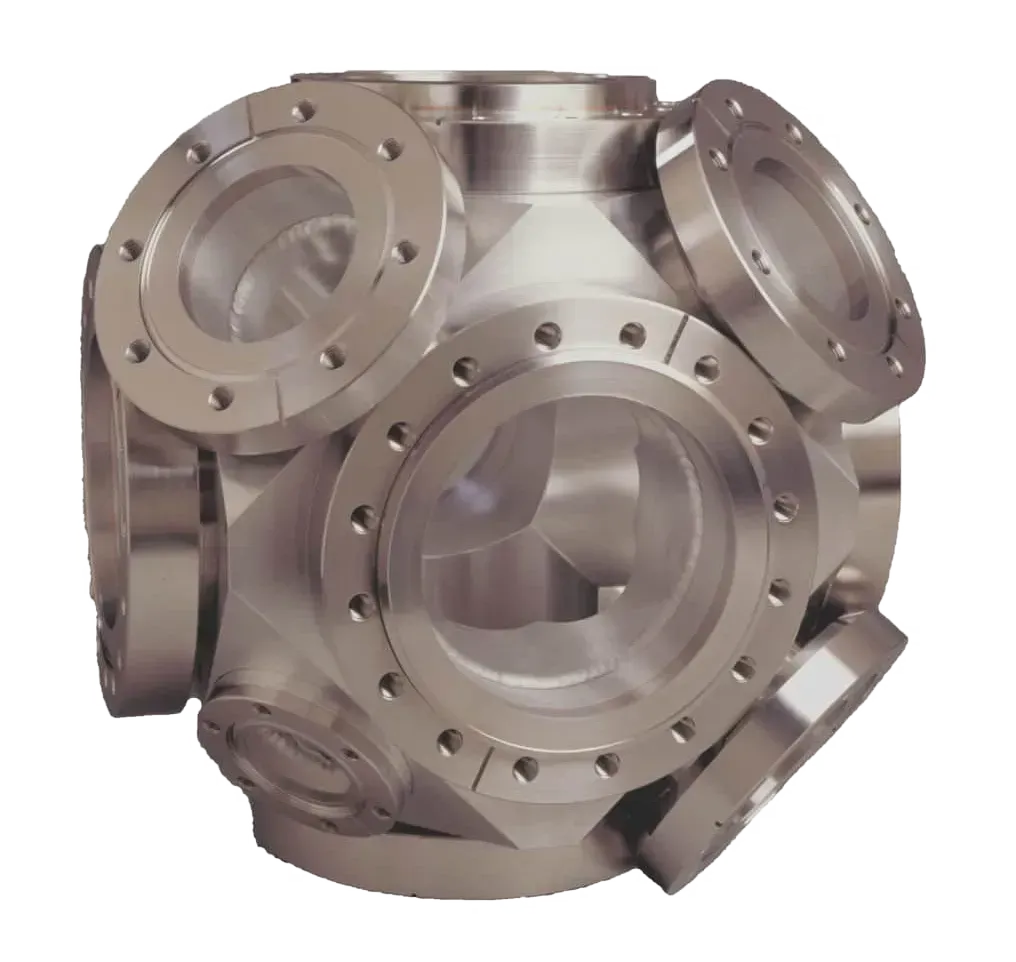

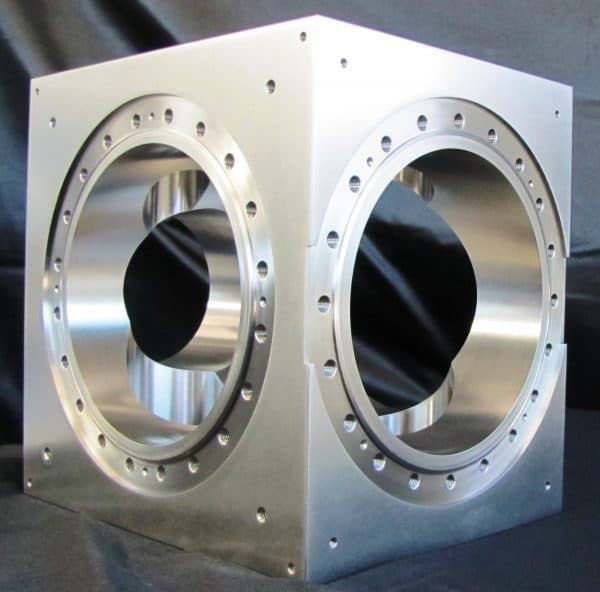

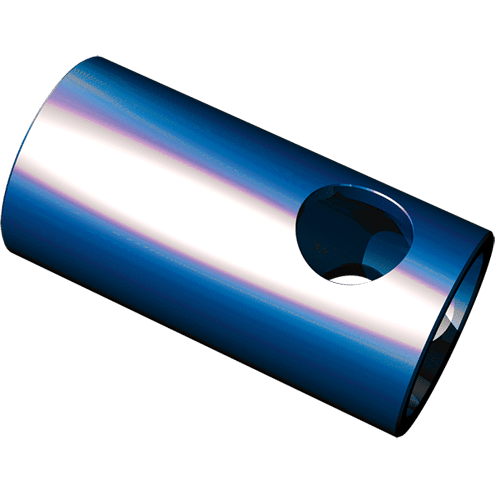

Titanium Vacuum Chambers

Atlas titanium vacuum chambers offer superb vacuum performance with very low hydrogen permeation rates and can even be utilized as vacuum pumps due to the gettering properties of this metal.

Titanium chambers can be taken into the 1×10-13 Torr range and beyond, so they are often chosen for extreme high vacuum (XHV) accelerator applications or for applications where performance is the primary concern.

- Particularly useful in aerospace and other high-performance applications

- Once activated, behaves as a getter to absorb hydrogen

- Superior XHV capabilities

- Low thermal conductivity

- No hydrogen for ultra pure vacuum

- No carbon for greatly reduced contamination

- Low thermal expansion

- Non magnetic for applications that require it

- Corrosion resistance

- 45% lighter than steel

- Yield tensile strength of 40—160 KSI

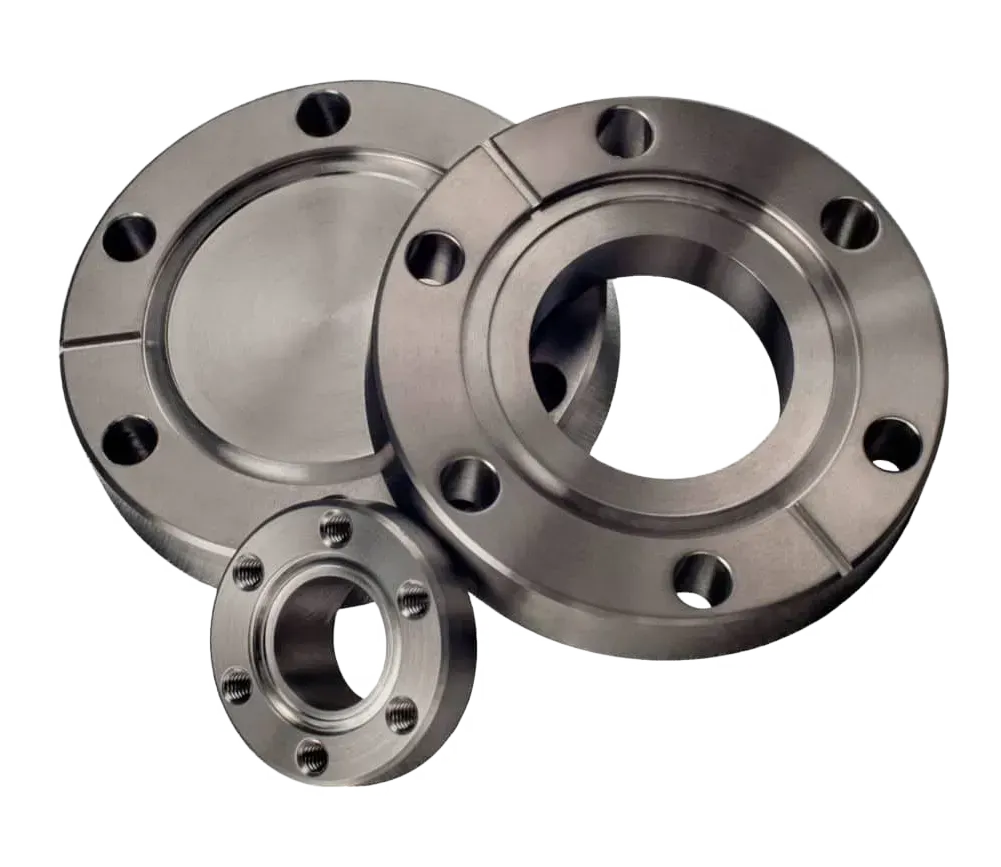

Atlas also manufactures a wide range of titanium vacuum components and accessory hardware to complement our titanium vacuum chamber products. Components include:

- Bimetallic Titanium/Stainless CF Flanges

- Wire-Seal Flanges

- Foil Window Flanges

Bimetal flanges offer a stainless steel sealing face on a titanium body. The stainless face matches the coefficient of thermal expansion of other stainless flanges while the titanium body is welded to the titanium chamber. For completely non-magnetic or stainless-steel-free applications, Titanium Flanges or Bimetallic Aluminum/Titanium CF Flanges can be used.

HOW CAN WE ASSIST IN YOUR PRODUCT DEVELOPMENT NEEDS?

From an aluminum chamber with titanium flanges for UHV suitcases to all titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a simple sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.