Bimetal Flanges & Fittings

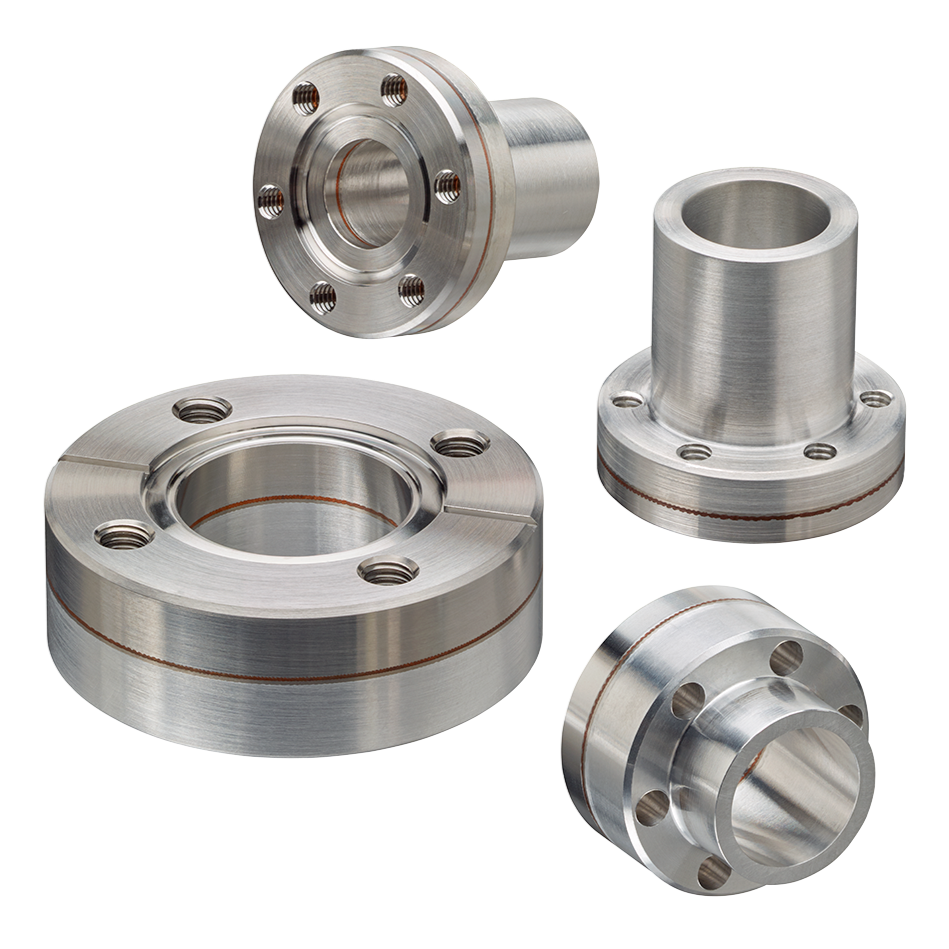

Bimetal CF Flanges

Atlas aluminum-stainless and titanium-aluminum bimetal flanges utilize the time-tested reliability of the ConFlat® (CF) knife edge to allow all-metal sealing and welding to aluminum and titanium vacuum chambers. Flanges are available in non-rotatable/rotatable Weld Neck, Tube Mount, and Flush Mount configurations.

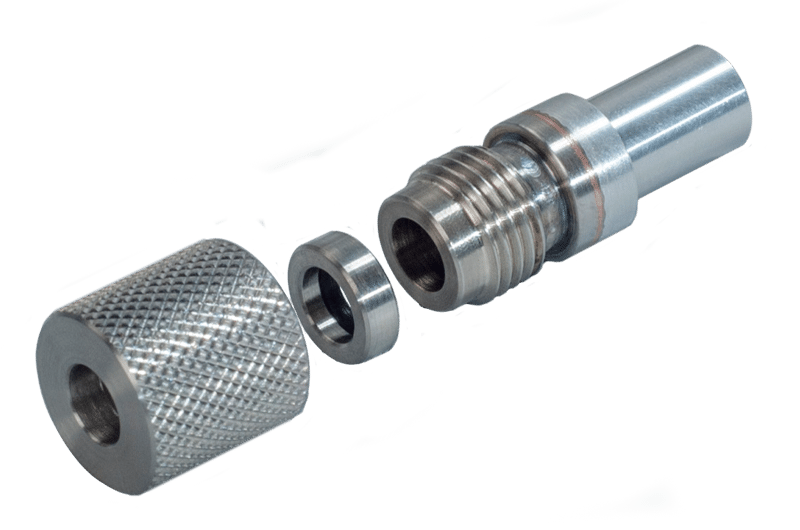

Bimetal Al/SS Face Seal Fittings

Atlas Face Seal Fittings enable robust, demountable use of aluminum tubing in cryogenics, physics research, and semiconductor applications where high thermal conductivity and high chemical resistance is required. Fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® designs.

Bimetal Al/SS Tube & Pipe Transition Fittings

Atlas bimetallic transition fittings enable the direct coupling of dissimilar metal tubes and pipes with different thermal conductivities. Used in cryogenic, nuclear, and industrial applications requiring contrasting heat transfer or where the properties of one metal must be reliably switched to that of another.

Bimetal Al/SS Neutron Windows

Atlas Bimetal Neutron Windows feature an Atlas CF flange with a 316L sealing surface and integrated aluminum window. The limited neutron-induced radiation inherent in aluminum enables use in cyclotrons and nuclear reactors.

Bimetal Al/SS Wire Seal Flanges

Atlas Al/SS Wire Seal Flanges are ideal for applications requiring a lightweight, demountable option for large sealing surfaces. With a stainless-steel sealing surface to crush a wire gasket, along with an aluminum body, these flanges allow weld-up to UHV aluminum chambers.

Bimetal Al/SS Quick Disconnect Fittings

Atlas Quick-Disconnect Bimetal Fittings quickly and easily connect tubular vacuum components such as feedthroughs, gauges, and glass tubing to aluminum vacuum systems.

HOW CAN WE ASSIST IN YOUR PRODUCT DEVELOPMENT NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a napkin sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.